0.1mm High Precision Pipeline Capsule Metal Detector Tablet Metal Separator

The high precision capsule tablet metal detector is designed to detect and remove minute ferrous, non-ferrous and stainless steel contaminants from tablets without interrupting production. The metal detector chute can be quickly and easily removed for routine cleaning and product changeovers. The pipeline capsule tablet metal detector system meets the hygienic requirements of the pharmaceutical industry and can be combined with all high-performance tablet presses with dust extraction. You are welcome to contact us at any time for quotation.

High precision capsule tablet metal detector photos

1. The high precision capsule tablet metal detector is particularly suitable for tablet presses and capsule filling machines to detect magnetic and non-magnetic metal impurities, quickly remove impurities from the production line, do not affect the normal production process, and reduce material losses. This machine can be used with any type of tablet press and capsule filling machine, or as a stand-alone unit.

2. Site: This high precision capsule tablet metal detector can be used with any type of tablet press and capsule filling machine, or as a stand-alone unit.

3. The detection coil is made of stainless steel and is completely sealed inside. One-time perfusion fixation.

4. The system is suitable for industrial environments with vibration, impact, and static interference, and is used to detect materials containing water or metal elements.

5. Modular structure: The system control box, detection head, rejection unit, and frame are separate for easy cleaning and maintenance.

6. The most advanced micro-process control system with self-learning function.

7. High precision capsule tablet metal detector meets national standards, is suitable for long-term production applications, and has stable performance.

Type: SG-YJ60

Feed port height and size: Height: 770-930mm Feed port size: 76mm

Height and size of outlet: Height: 770-860mm Size of outlet: 51mm

Effective passing size: W70*H20mm

Maximum production capacity: 500,000 pcs/hour

Detection sensitivity: Fe: 0.4mm, stainless steel: 0.6mm

Machine weight: 75kg

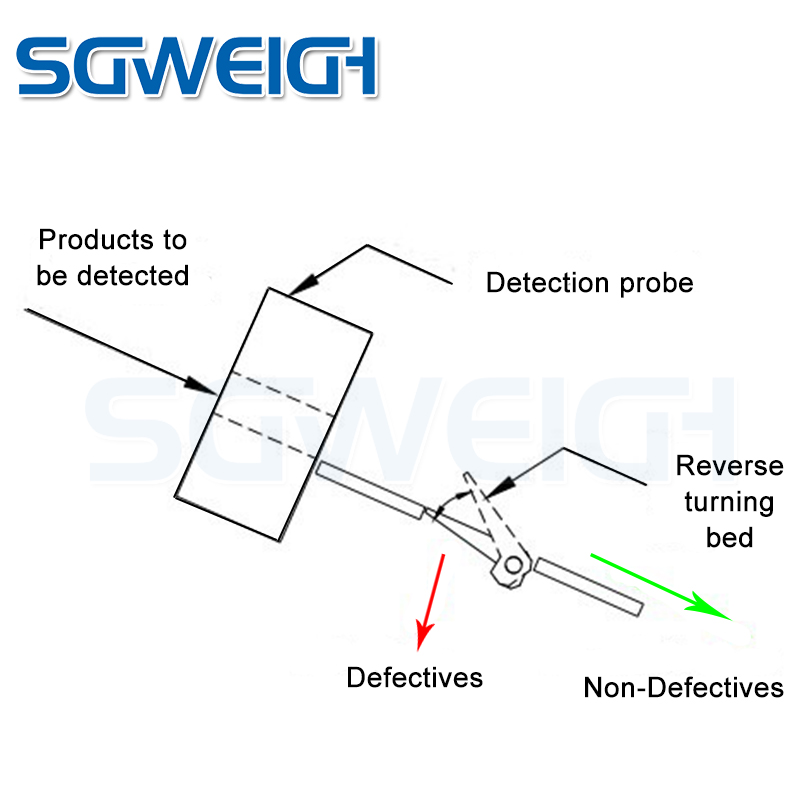

Removal method: flip culling

Working voltage: 220V/110V, 50/60HZ

Equipment dimensions: 1115*550 (1280-1400) mm

0.1mm High Precision Pipeline Capsule Metal Detector Tablet Metal Separator

This high precision capsule tablet metal detector is customize according to customer requirements and may not meet your requirements. The design of the pipeline metal detector must take into account factors such as the speed of the production line, the accuracy of the detection, and the impact on the material. It can be customize according to specific requirements. We provide a variety of metal detector solutions free of charge. Please feel free to contact us.

This high precision capsule tablet metal detector is use to detect metal impurities in pills, tablets and capsules after tableting and dust removal. It can detect all metal impurities, including ferrous metals (Fe), non-ferrous metals (copper, aluminum, etc.) and stainless steel.

0.1mm High Precision Pipeline Capsule Metal Detector Tablet Metal Separator

Plastic packaging is use for the inner part, and stronger wooden boxes will be use for the outer part.

Our standard packaging process:

1) Dust removal and cleaning

2) Lubricate drive parts

3) Divide the machine into modules

4) Wrap the modules with plastic film

5) Pack the modules into plywood boxes

6) Mark the shipping mark on the boxes

If there are any special requirements, we will pack as required.

1. Consultation and Evaluation: Understand the customer’s requirements, production processes and quality control goals to determine the machine solution that best suits their specific needs.

2. Product Demonstration: Visually see the equipment in action and directly evaluate its performance.

3. Installation and Commissioning: After purchase, the machine is install and commissioned by trained technicians to ensure it operates correctly and integrates seamlessly into the customer’s production line.

4. Technical Support: Provide ongoing technical support to resolve any questions, problems or maintenance needs that arise during machine operation.

5. Warranty Coverage: 1 year warranty, lifetime repair.

We aim to provide customers with the right solutions, support and peace of mind throughout the life cycle of the equipment, ensuring that the machine meets the customer’s needs and provides long-term value.

Related Products

Dual Weighing System Checkweigher For Small Package

Small Size Pharmaceutical Checkweigher For Tablet Capsule

High Speed Conveyor Checkweigher System

Food Incline Conveyor Belt Metal Detector Machine

Tablet And Capsule Metal Detector For Nutraceutical

Cosmetic Spray Turntable Weighing Check Weigher

High Accuracy Checkweigher And Metal Detector

Durable Multi-Lane Packing Machine For Liquid Candy

Easy Operation Sprays Bottles Rotary Weighing Checkweigher

Hot Labels: 0.1mm,high precision,pipeline,capsule,metal detector,tablet,metal separator,manufacturer,supply,factory,price