Dynamic Inline Heavy Duty Weight Checker Conveyor Industrial Checkweigher

Inline heavy duty weight checker is for 0.5-50kg big heavy weight package, reject non-good weight by alarm stop belt or air-pusher, weight checking section is by belt and reject part is in roller-conveyor. Due to its modular design, the conveyor industrial checkweigher machine is easy to install and occupies a small area. The checkweigher can be easily integrated into new or existing production lines. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

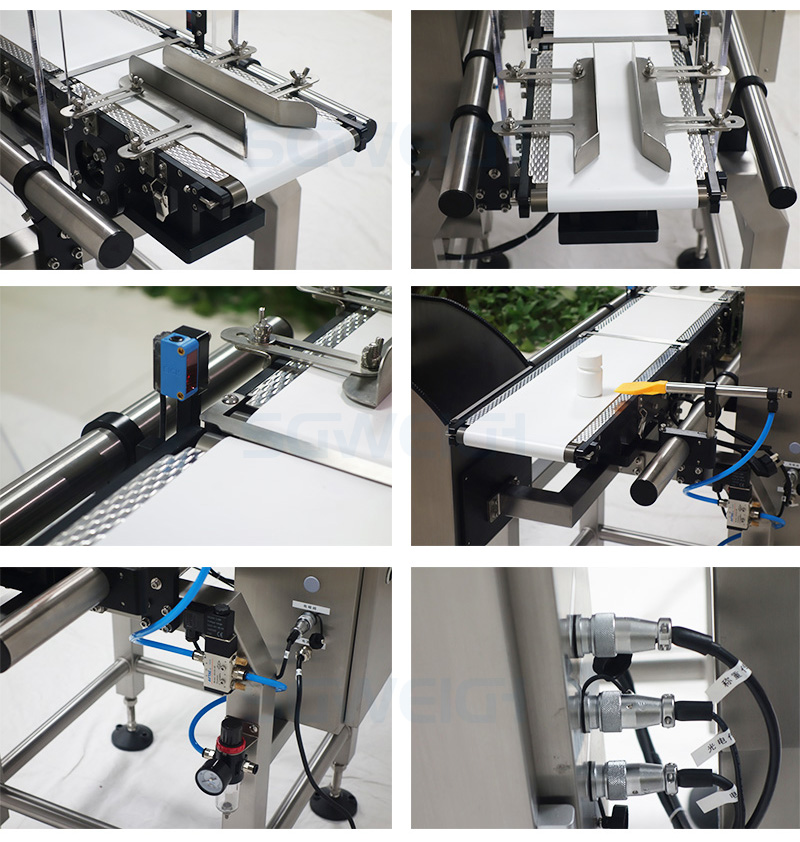

Inline heavy duty weight checker photos

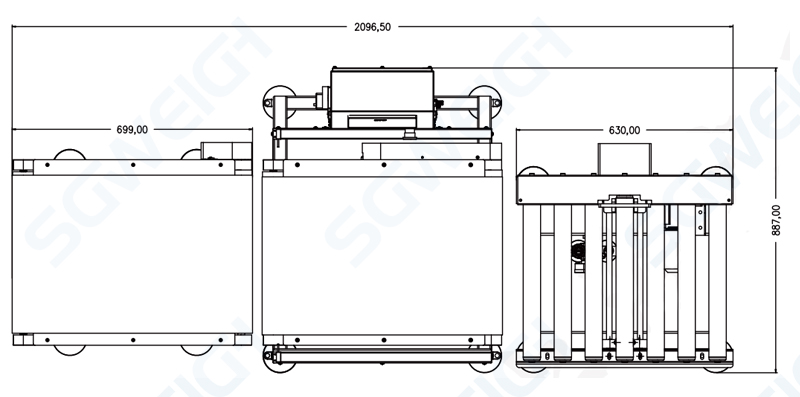

Type SG-450

Weighing Range 0.05-25kg

Limited of product L: 550 W:450 H: 3-400mm

Accuracy ±5/10g

Division Scale 1g

Belt Speed 0- 60 m/min

Max Speed 40 pcs/min

Belt Width 450mm

Machine Weight 40kg+70kg+45kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

We mainly provide high-quality machinery from four aspects:

(a) Working life: about 10 years.

(b) Good stability: Stability is the basic and most important performance of machinery.

(c) Reduce the daily maintenance cost of the machine.

(d) Before all machines are delivered, our quality control staff will check carefully to ensure quality.

Inline heavy duty weight checker is suitable for standard inspection of assembly line single products and sample weights. It is widely used in food, medicine, packaging, printing, logistics equipment, IT digital, home appliances, stationery and toys, precision manufacturing, agricultural product processing and other industries.

Strong stainless steel 304 structure

Reliable and stable weighing control system

High speed digital filter processing and automatic zero tracking function

Humanized operating system, easy to learn and operate, a variety of language versions available.

Operation display: 8 Inches Color Touch Screen

Product Storage: 100 kinds of product preset

Weighing data output: USB port to download data into Excel.

Rejecting system: Pusher with alarming light

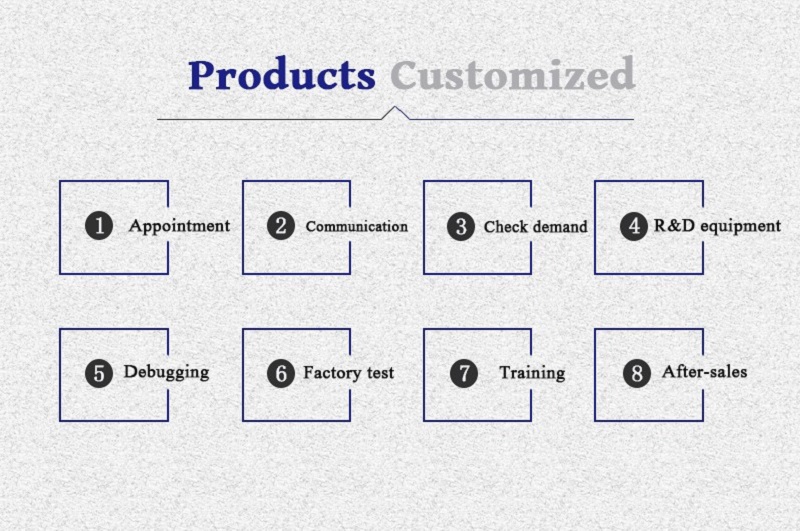

OEM/ODM customers receive comprehensive technical support and after-sales services from inline heavy duty weight checker manufacturers, including installation assistance, operator training, troubleshooting and maintenance services.

The technical support team is available to resolve any questions or issues related to the entire life cycle of your custom checkweigher system.

From 2010 to present, we have our own factory and provide processing support, design and manufacturing automated testing production lines for many well-known companies. Shanghai Shigan has cultivated a group of outstanding technical personnel and management talents, focusing on the checkweigher industry, constantly innovating, and has obtained multiple patent certificates. It is committed to the research and development of various checkweigher and metal detector models.

Our main products:

Checkweigher Machine、Automatic Check Weigher、Capsule Tablet Checkweigher、Checkweigher with Labeling Machine Combo、High Accuracy Checkweigher、High Speed Checkweigher、Inline Weight Checker、Multi-lane Checkweigher、Weight Sorting Machine、Digital Metal detector、Capsule Tablet Metal Detector、Checkweigher and Metal Detector Combo、Food Metal Detector、Industrial Metal Detector、Pharmaceutical Metal Detector

1.Before packaged, the machines will be test strictly to guarantee the stability and high accuracy.

2.After tested, the machines will be wrapped with plastic sheet and carefully packed in wooden cases.

Over the years, Shanghai Shigan Industrial Co., Ltd. has been serving customers in the melt industry, after research, exploration, summed up a complete set of product and service support system to provide users with high quality and timely pre-sale, sale, after-sales service:

First, quality assurance

My business department to ensure that the equipment provided to customers is the original production, and factory information accessories complete. In order to maintain the normal operation and maintenance of the contracted equipment, the technical products provided by our department are complete, clear and correct.

Second, quality assurance measures

Warranty period: one year warranty and lifetime maintenance. During the warranty period, accessories damage by non-human factors will be replace free of charge; outside the warranty period, accessories will be provide at cost price.

Related Products

Chicken Leg Steak Multi-level Weight Sorting Machine

Checkweigher and Metal Detector Combo for Daily Necessities

Frozen Seafood Automatic Metal Detector Waterproof

Industrial Checkweigher with Labeling Machine Combo for Box

Bottles Rotary Checkweigher for Pharmaceutical Factory

0# Capsule Tablet Sample Checkweigher

Hot Labels: dynamic,inline,heavy duty,weight checker,conveyor,industrial,checkweigher,solution,price,factory