To detect hollow capsules, the high precision capsule checkweigher must have these advantages

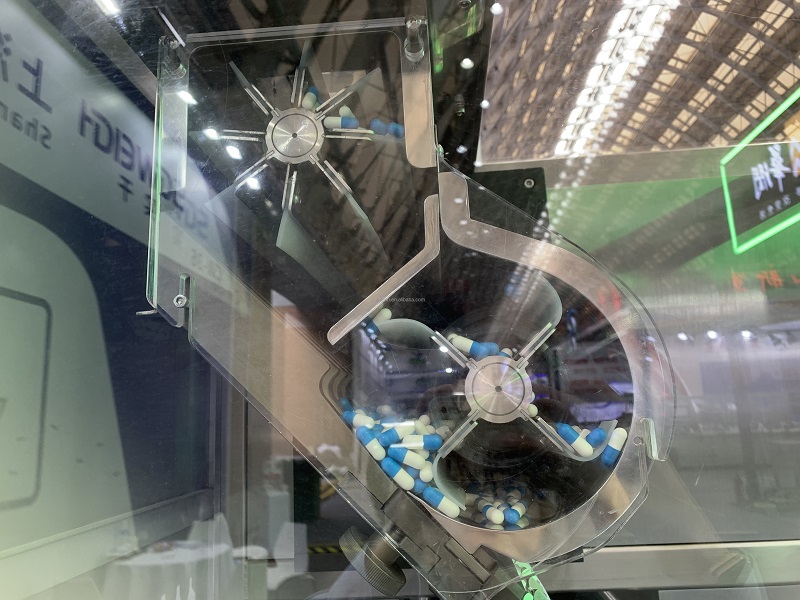

As we all know, capsules are small in size, light in weight and large in quantity, so weight detection is a difficult problem. Hollow capsules without fillers are lighter in weight, and the capsule cap and capsule body can be easily unlocked during the material sorting and dispensing process before testing. Therefore, the weight detection of hollow capsules places higher requirements on high precision capsule checkweighers. Sitek Checkweighing will tell you in detail the inherent advantages of the slide-type capsule checkweigher for detecting hollow capsules.

1. There is no need to change the material handling and weighing molds. One set of molds can adapt to a total of 8 types of hollow capsules from #000 to #5. It can also adapt to various extended type, DB type and other hollow capsules. The benefits are as follows:

1) Rapid sampling and testing of hollow capsules of different batches, models and materials from various workshops and all production lines can be carried out at any time. There is no need for adjacent models or even hollow capsules of the same model to be equipped with a set of material management and hair molding tools.

2) Equipped with a large silo of nearly 100 liters, it can greatly reduce the number of times the operator loads materials during full inspection of large batches.

3) There is no need for complex and time-consuming calibration work such as matching detection and debugging of capsules and material transfer mechanisms, and weight calibration of different types of capsules, which are essential after each mold replacement.

4) No special storage cabinets and spaces are required to store molds and disassembly tools.

5) Frequent replacement of the capsule material dispensing module will not damage the delicate sensors or harm the operator.

2. The capsules will not be unpacked during the queuing and feeding process (making the hollow capsule disintegrate), and the feeding channel will not be blocked as a result.

3. In the capsule queuing process, there is no up and down large-stroke ejection mechanism used to activate the capsules for rapid queuing. There is no large-scale repeated friction between the hollow capsules in the silo, which will not generate a large amount of static electricity and will not affect subsequent weighing. Heavy or even subsequent capsule filling or blister packaging processes may cause electrostatic adsorption.

4. There is no secondary forced compression stop mechanism for the capsule queue arranged up and down. The capsule will not be broken or compressed during the capsule dispensing process. There will never be any unlocked capsules and caps in the finished product, and there will be no hollow capsules. Fragmented or deformed capsules.

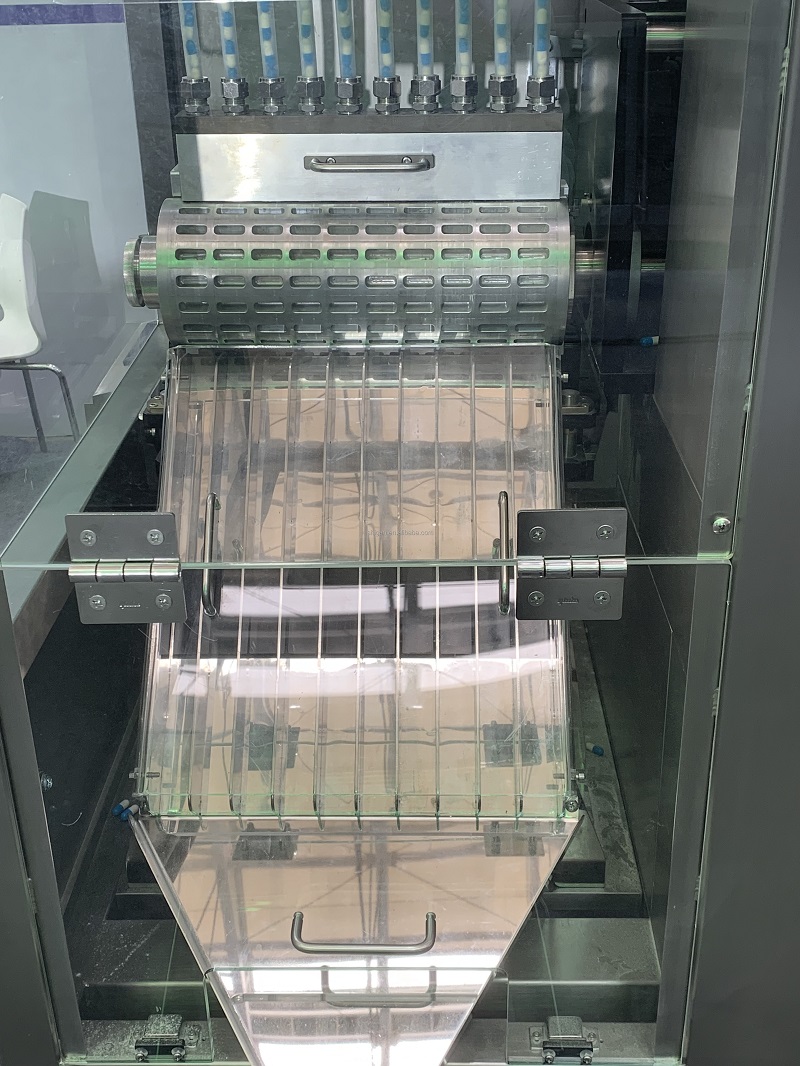

5. The process of moving the capsule after weighing is completely based on the capsule’s own gravity. There is neither a cylinder ejection and contraction pull-back device nor a rotating gear structure:

1) The capsule transfer process after weighing will never be unpack, and the hollow capsules with qualified weight after weighing will not be decomposed into capsule bodies and capsule caps by the material transfer mechanism and then enter the finished product barrel at the same time.

2) The sensor is not subject to the reciprocating linear collision force, retraction force or rotational force of the capsule transfer mechanism. There is no hidden danger of damage to the sensor, and large loads are not frequently applied to it. The weighing accuracy is long-term and reliable, and there is no need to frequently shut down the machine for zero point tracking. .

3) Finished products or fragments are automatically moved out of the scale platform by gravity. There will never be any damage to the weighing sensor when the ejector rod is retracted because the fragments are caught between the ejector rod and the central slot of the scale platform. The debris clamped between the top of the gear teeth and the scale platform damages the load cell when the gear teeth are forcibly rotated, making the equipment extremely reliable.

Thank you for your interest in our wide range of high-precision capsule checkweighers. Please feel free to leave information about your specific requirements and we will customize the machine for you.

Related Products

120g Mini Online Checkweigher High-Speed Checkweigher

High Sensitivity Tablets Capsule Metal Detector

Automatic Printing Scanning Checkweigher Labeling Machine

SG-T300 Mineral Water Bottle Checkweigher Labeling Machine

Bottles Rotating Checkweigher Real-time Weighing Checkweigher