SG-400 Roller Assembly Line Online Weighing Checkweigher Manufacturer

This assembly line automatic checkweighers adopts a high-speed dynamic weighing algorithm to detect whether a single weight matches the target weight, and to eliminate overweight and underweight products, which can effectively control product quality. The modular design of roller conveying online weighing checkweigher makes the operation and daily maintenance of this series very simple, and it is also easier to meet the requirements of different users. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Assembly line automatic checkweighers pictures

Type SG-400

Weighing Range 100-10000g

Limited of product L: 450 W:400 H: 3-400mm

Accuracy ±1g-10g Depends on product

Division Scale 1g

Belt Speed 0- 60 m/min

Max Speed 50 pcs/min

Belt Width 400mm

Machine Weight 110kg

Power Supply AC 220V 50HZ

Power 300W

Main Material SU304 stainless steel

Provide the following information to our sales personnel, and our team will support you in selecting the correct type of dynamic checkweighers:

*1. Main parameters of the tested product, product size range: length, width, height

*2. Accuracy requirement: ± g.

*3. Speed requirement: pcs/min;

*4. Product weight range:; The maximum and minimum deviations of the same product.

This assembly line automatic checkweighers is mainly suitable for weight detection of production line terminal packaging or sorting of large weight, large volume boxes, barrels, bags in beverage and logistics transportation systems. It is widely used in industries such as chemical, feed, rice, logistics, etc.

1. Ultra high adaptability to equipment environment.

2. Extremely user-friendly operation interface.

3. You can modify parameters at any time without the need for the weight sorting machine to pause sorting.

4. Up to 200 product presets can store hundreds of thousands of data records, meeting the complex needs of customers.

5. Rich peripheral resources make it easy to connect with other devices.

6. The rapid dynamic weighing algorithm software technology enables the entire system to maintain high detection accuracy even during high-speed operation.

Shanghai Shigan Industrial Co., Ltd. is a professional company that designs, produces, and sells checkweigher machines, and metal detector machines, widely used in packaging industries such as medicine, food, chemical, daily necessities, and hardware. The company is located in Shanghai, China, with a strong research and development team, complete production technology, and strict mechanical inspection standard system. We adhere to the spirit of pioneering and enterprising, focusing on high-quality machine innovation and production. According to customer requirements, we sincerely welcome you to our long-term business cooperation.

Main products

Free export fumigation plywood box with quick connection design, easy to open and reuse;

Internal plastic film packaging can protect goods from salt, wind, or damage;

Our transportation methods include diversification, and we can choose transportation methods based on customer needs, including sea, land, and air transportation. We are all supported.

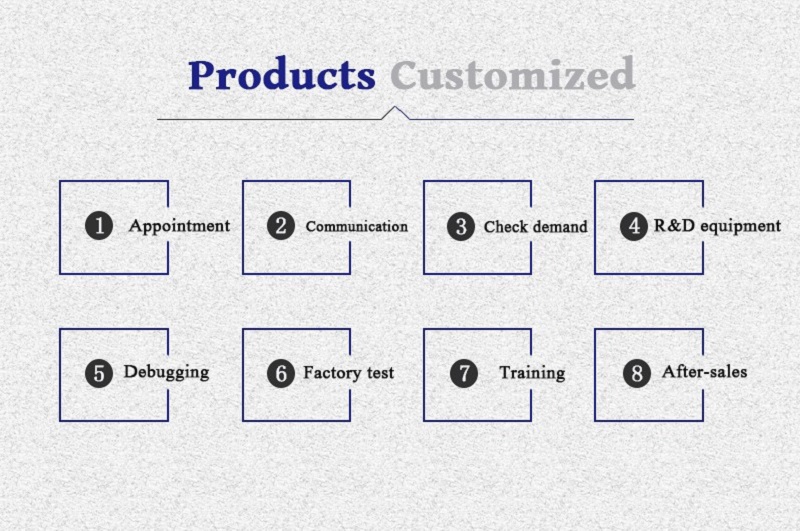

Our services

1. Provide new products that meet market demand.

2. Before confirming the order, samples can be tested for free.

3. Warranty period: After the machine is sold out, the warranty period is one year, with lifelong service.

4. Training services: After ordering, the machine user manual and installation video will be provided.

5. Certification: We provide relevant certificates to customers for free according to their requirements.

6. Maintenance Service: We promise to respond within 24 hours if any malfunctions occur and assistance is needed.

Related Products

Food Industry Metal Detector For Factory

Capsule Tablet Dynamic Checkweigher Customized

Quantitative Industrial Checkweigher Roller

Automatic Weighing Printing Conveyor Line Checkweigher

Double Bottle Rotary Weighing Checkweigher System

SG-400 Online Box Checkweigher for 10kg Conveyor

Hot Labels:SG-400,roller,assembly line,online,weighing,checkweigher,anufacturer