SG-10XM Small Pouch High-speed Multi-lane Checkweigher Machine Online Checkweigher

High-speed multi-lane checkweigher is a high-precision and high-efficiency automatic weighing equipment suitable for various production line environments. Online multi-lane checkweigher machine adopts advanced sensor technology and intelligent algorithms to perform simultaneous, fast, and accurate weight detection and sorting of multiple items. Our product specifications and sizes are rich, various styles, welcome to contact us for quotation information.

High-speed multi-lane checkweigher photos

Type SG-10XM

Weighing Range 2-300g

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Each Channel Speed 70 pcs/min

Belt Width 30mm

Machine Weight 200kg

Power Supply AC 110/220V ±10% 50HZ

Power 300W

Main Material SU304 stainless steel

Provide our sales personnel with the following information, and our team will support you in selecting the correct type of high-speed multi-lane checkweigher:

*1. Main parameters of the tested product, product size range: length, width, height

*2. Accuracy requirement: ± g.

*3. Speed requirement: pcs/min;

*4. Product weight range:; The maximum and minimum deviations of the same product.

1. 10 inch color touch screen, easy to operate.

2. Quick belt replacement system; Adopting a buckle design, cleaning the belt is very easy.

3. Up to 10 shortcut menus, seamless integration for product switching, achieving non-stop product switching.

4. Unqualified product query printing

5. Provide feedback signals on production trends, adjust the packaging accuracy of upstream packaging machines, improve user satisfaction, and reduce costs.

6. All core components are made of imported accessories to ensure the stability of equipment operation

7. Independent processing plants enable lower costs and the most affordable prices for equipment of the same grade.

8. The domestically produced high-quality separation and removal device prevents the product from falling down and spilling materials during the sorting process, ensuring the integrity of the tested material.

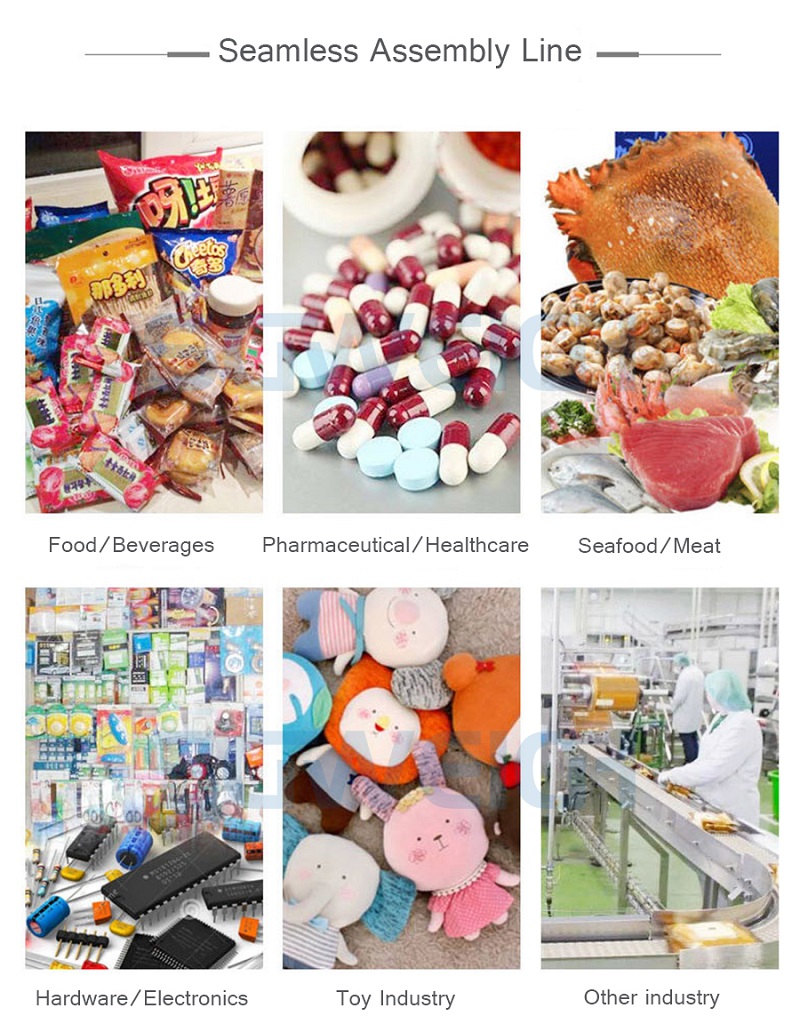

1. Food industry: bagged or canned foods such as rice, candies, beverages, nuts, bread, biscuits, cooking oil, instant noodles, seasonings, puffed foods, snacks, etc.

2. Pharmaceutical industry: whether the tablet drug has fewer or more pills; Is there a shortage or multiple bags of medicine in powder bags; Whether the weight of liquid drugs meets the standard; Drug attachment missing detection (such as instructions, desiccants), etc.

3. Daily chemical industry: weighing detection of the net content of sanitary napkins, paper towels, diapers, cosmetics, wet paper towels, facial mask, shampoo, shower gel, cleaning, washing powder, washing liquid and other household products/detection of missing parts in a whole box/multi-level weight sorting; Detection of missing parts in daily chemical products packaged in boxes, bags, boxes, etc; Daily chemical products have unqualified net content testing, and packaging accessories such as instructions/desiccants/accessories have missed packaging testing.

4. Hardware industry: detection of multiple or missing parts in industrial components, processed parts, and semi-finished products; Small parts missing parts detection: such as toy missing parts detection, screw missing package missing parts detection, TV and set-top box products missing parts detection.

Our manufacturer has ISO9001, CE international certification,

1. More than 11 years of production experience

2. More than 10 years of foreign trade experience

3. More than 10 national technology patents

4. Cumulative overseas sales exceed 1,000 sets

5. Comply with EN60204 international standard

6. Our main products

1. Packaging materials: International standard export packaging boxes are usually used, which have good wear resistance, shock resistance, and waterproof performance. The material of the box can be hard wooden boxes, plastic boxes, or export specific cardboard boxes.

2. Protective measures: In order to ensure that the weigher is not damaged during transportation, it is necessary to add sufficient filling materials, such as foam, shockproof cotton, etc., into the packaging box.

3. Identification and Marking

12 Months Guarantee

★ 12 months free main parts change (Please return the damaged parts by airmail)

★ Overseas engineers available (You only have to pay part of the freight)

Customization

All our machines can be customized , according to your product’s features and your workshop environment, or your production line.

After-sales Service Provided

Engineers availbale to provide after-sales service overseas in order to help customers solve technical problems.

Related Products

SG-1X Small Packaging Balance Grade Checkweigher

SG-JN10 Dynamic Single Capsule Tablet Checkweigher

SG-D300 Multi-level Weight Sorting Machine

SG-T300 Checkweigher and Labeling Machine Combo

High Speed Capsule Tablet Sampling Checkweigher

SG-220 Standard High Performance Checkweigher

Hot Labels: small pouch,high-speed,multi-lane checkweigher,checkweigher machine,online checkweigher,supplier,manufacturer