Real-time Printing Food Checkweigher and Labeling Machine Weighing Labeller

The food checkweigher and labeling machine can weigh the packaged items while running at high speed to complete the positioning and labeling of the packaging. The labeling head has various forms and labeling methods. Air blowing, rotating and stamping labeling heads are optional. The modular design of the real-time printing checkweigher and labeling machine is also quite outstanding in terms of flexibility, durability and easy maintenance. For further information about our services, or if you would like one of our professionals to contact you, please do not hesitate to contact us.

Food checkweigher and labeling machine photos

- Printing Width: 104mm

- Printing Length: 1651mm

- Distinguishability:300dpi

- RAM:4M SDRAM

- Label width: 20mm~115mm,

- Label Size:external diameter 203mm; inner diameter 76mm

- Label thickness: 0.076mm~ 0.305mm

- Label medium type: continuous paper, die cutting paper

- Labeling Section

- The standard precision: ±1mm

- Labeling speed: 0-15 pieces/min

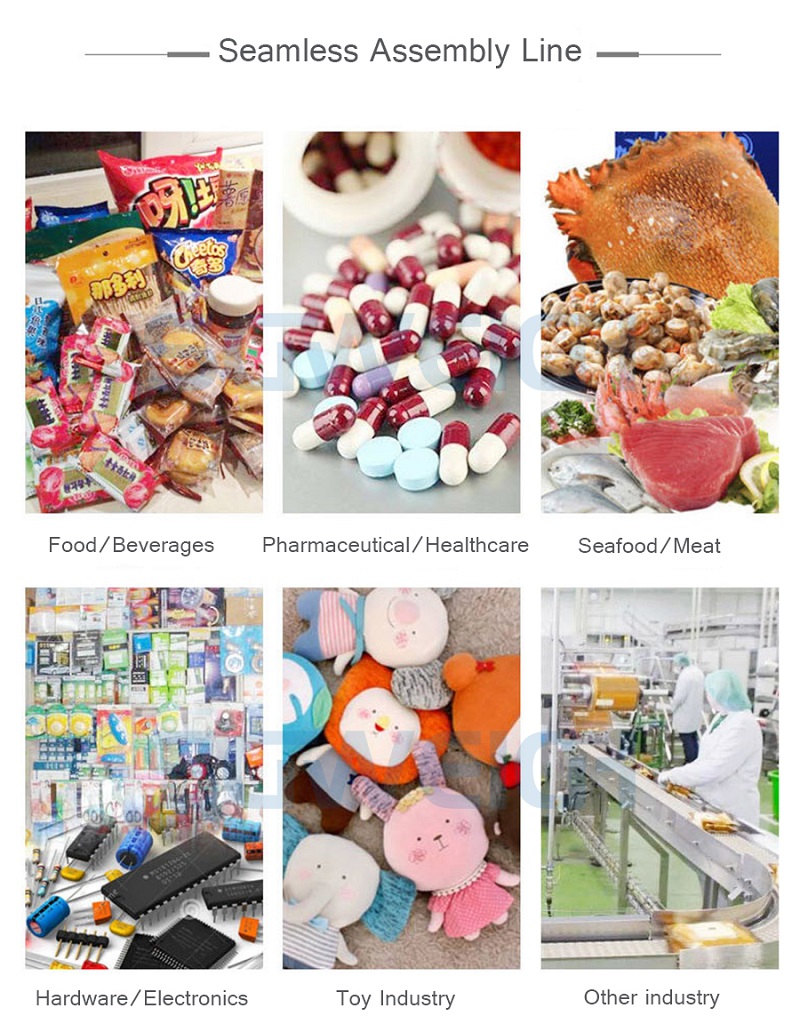

Real-time printing checkweigher and labeling machine is suitable for various round and square bottles, boxes, cans, jars and other flat items, such as stationery, CDs, cartons, boxes, fruit and vegetable tray bags, etc.

1. Large-size color LCD touch screen interface, simple operation and direct display.

2. Enhanced 304 stainless steel frame, GMP and HACCP standards.

3. The mechanical structure is simple and can be quickly removed for cleaning and maintenance.

4. Can store 200 product parameters for user convenience.

5. Automatic zero-point tracking system to ensure the stability of detection.

6. Built-in temperature and noise compensation system to ensure reliable data.

7. Dynamic weight compensation technology ensures data is more effective

8. Parameter settings are password protected and only manage operations.

9. Powerful self-diagnosis function effectively improves the efficiency of operators in handling faults.

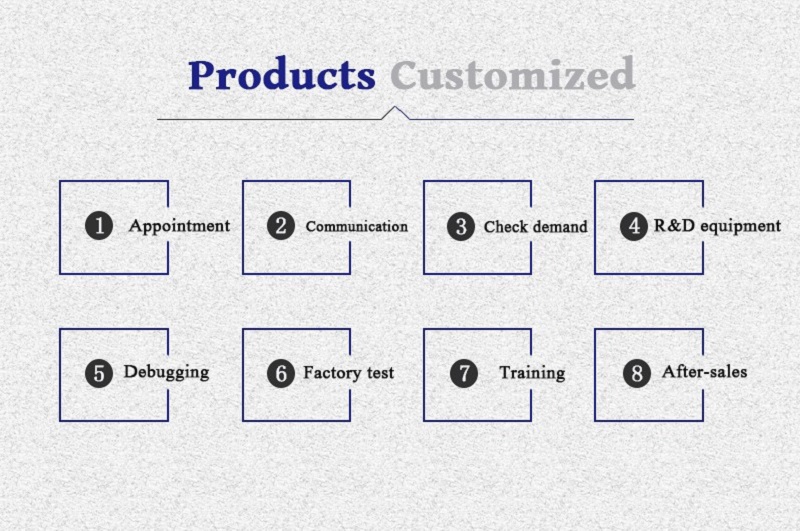

The food checkweigher and labeling machines displayed may not meet your requirements. We have professional technical staff to provide professional customized solutions based on the user’s product characteristics and application scenarios.

If possible, please let us know more details about your project, such as material, weight range, speed, bag size, etc.

Shanghai Shigan Industrial Co,. Ltd has been a professional checkweigher manufacturer since 2010. We have a strong R&D team, R&D innovation is our purpose, and the market is our guide. Shanghai Shigan has CE certificate and has been sold to many foreign countries. We enjoy a reliable reputation among our customers due to professional service, quality products and competitive prices. Our mission is to manufacture high-quality machines; to help customers improve the quality and efficiency of their products. The products are sold all over the country and exported to Russia, Siberia, Inner Mongolia, Vietnam, Myanmar, Southeast Asia, Africa and other countries and regions. The company wholeheartedly welcomes new and old customers to visit and cooperate sincerely to create a better future.

- The inner packaging is plastic film and the outer is wooden or plywood box

- Plastic film bare packaging with plastic pallet only.

- We can provide fumigation packaging and certificates.

- Transportation, training, express delivery or according to customer requirements.

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer problems encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of the accessories and meet the needs of users.

4. One-year warranty and lifetime maintenance

6. After-sales service tracking: Track and provide feedback on the after-sales service process, understand customer needs and opinions in a timely manner, and continuously improve service quality.

Related Products

High Precision Assembly Line Empty Capsule Checkweigher

Inline Box Check Weigher For Food Industry Rejector

Big Bag Carton Metal Detector Conveyor Price

High Performance Bottle Rotary Checkweighers

Pharmaceutical Sample Checkweigher for Capsules

Strip Pack Multi Lane Checkweighers for Daily Necessities

Hot Labels: real-time,printing,food,checkweigher and labeling machine,weighing labeller,factory,manufacturer,price