Precision Cosmetic Bottle Checkweigher Inline Weight Checker with Clamping Conveyor

Equipped with advanced load cells and a digital monitoring system, the bottle inline weight checker with clamping conveyor inspects each bottle in real time, quickly identifying underweight or overweight products. Its compact design seamlessly integrates into existing packaging lines, ensuring hygienic, efficient, and reliable operation. Designed for high-volume cosmetics production, the precision cosmetic bottle checkweigher quickly and accurately verifies weight, keeping pace with fast-moving production lines. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

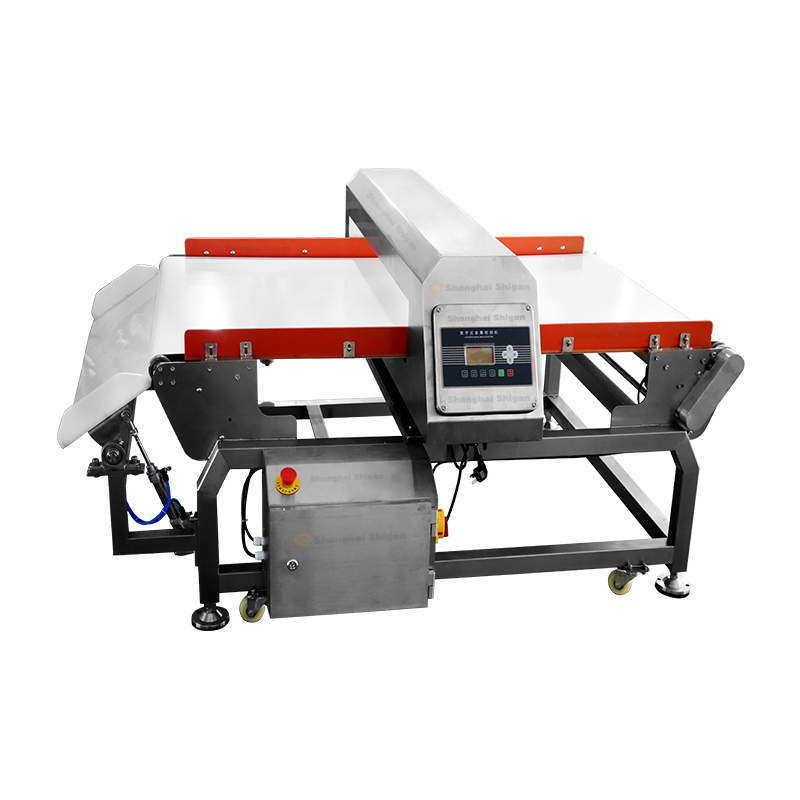

Bottle inline weight checker with clamping conveyor photos

Precision Cosmetic Bottle Checkweigher Inline Weight Checker with Clamping Conveyor

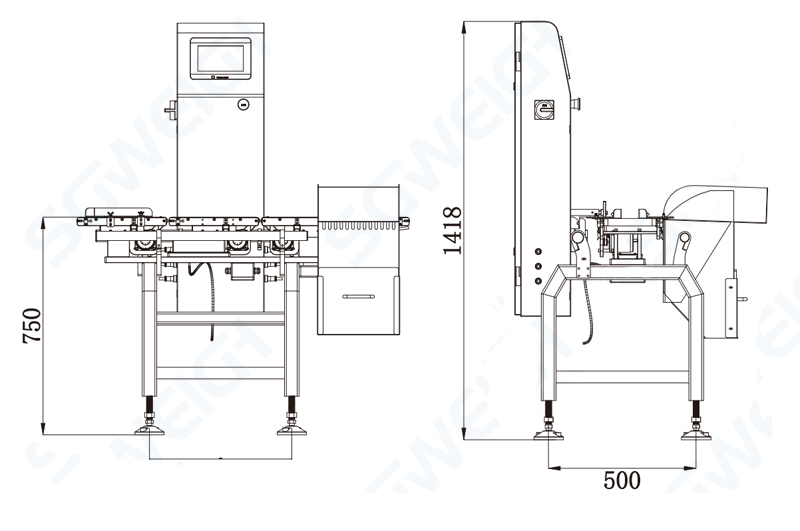

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. Fast and Accurate: High-speed weighing ensures real-time inspection of every bottle.

2. User-Friendly Interface: Easy operation and calibration reduce staff training time.

3. Compliance Ready: Meets GMP and ISO standards for cosmetic packaging.

4. Space-Saving Design: Compact footprint fits neatly into production areas.

5. Traceability & Data Export: Track results and generate reports for quality assurance.

6. Minimized waste and rework through immediate detection of deviations.

7. Optimized throughput without compromising accuracy.

8. Seamless integration with production monitoring systems.

9. Long-term reliability with durable construction.

10. Enhanced quality control across multiple cosmetic product lines.

1. Suitable for bottles of various shapes and heights.

2. The gripping conveyor allows bottles to stand upright after being dropped.

3. Customizable to meet various needs.

Our professional engineers will design the most suitable bottle inline weight checker with clamping conveyor solution for your production line, meeting the diverse needs of even the most complex production lines. In practice, we will also continuously optimize and improve the bottle checkweigher solution based on the production line’s operating conditions and customer feedback to ensure it always operates at its best.

Precision Cosmetic Bottle Checkweigher Inline Weight Checker with Clamping Conveyor

Packing Detail:

Each Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers and ship them abroad.

Delivery Detail :

Shipped in 25 days after payment

1. Consultation and Evaluation: We understand our customers’ requirements, production processes, and quality control goals, and determine the machine solution that best suits their specific needs.

2. Product Demonstration: We provide a visual demonstration of the equipment in action and a direct assessment of its performance.

3. Installation and Commissioning: After purchase, the machine is installed and commissioned by trained technicians to ensure correct operation and seamless integration into the customer’s production line.

4. Technical Support: We provide ongoing technical support to address any questions, issues, or maintenance needs that arise during machine operation.

5. Warranty Coverage: One-year warranty, lifetime repairs.

We aim to provide customers with the right solutions, support, and peace of mind throughout the equipment’s lifecycle, ensuring the machine meets their needs and delivers long-term value.

Related Products

Intelligent Checkweigher and Metal Detector Combo

Multi-Lane Checkweigher for Precision Weight Control

Inline Dynamic Checkweigher for 10kg Bags

Dynamaic Weight Controller for Capsule and Tablet

4 Lane Sachet Liquid Packing Machine

Capsule and Tablet Random Inspection Checkweigher

800 pcs/min Ultra-Fast Dynamic Checkweigher

Industrial Turntable Checkweigher for Bottling Line

Automatic Metal Detector for Capsules and Tablets

Pharmaceutical Capsule Intelligent Weight Checker

Hot Labels: precision,cosmetic,bottle checkweigher,inline,weight checker,lamping conveyor,quote,price,factory,manufacturer,supplier