Industrial Checkweigher with Dual Reject System Dynamic Checkweigher Conveyor

The industrial checkweigher with dual reject system is an advanced weighing solution designed for accurate, reliable, and rapid weighing, ensuring that every product on the production line meets the highest standards. This dynamic checkweigher conveyor employs a dual-rejection mechanism to separate underweight and overweight products, guaranteeing that only products with accurate weight are delivered to the customer. You are welcome to contact us at any time for quotation.

Industrial checkweigher with dual reject system photos

Type SG-100HH

Weighing Range 2-300g

Limited of product L: 100 W: 100 H: 2-150mm

Accuracy ±0.05g Depends on product

Division Scale 0.01g

Belt Speed 0- 120 m/min

Max Speed 450 pcs/min

Belt Width 100mm

Machine Weight 150kg

Power Supply AC 220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Industrial Checkweigher with Dual Reject System Dynamic Checkweigher Conveyor

How to select a high accuracy industrial checkweigher?

1. Determine the series based on the size, weight range, and application of the product you need to weigh.

2. Determine the appropriate rejection system based on your product.

3. Determine the height and width (if any) of your existing production line, and the space required by our company.

4. Determine the optional functions you need; such as USB data storage, real-time weight data transmission, alarms, etc.

To provide more accurate parameters, solutions, and quotations, we recommend that you contact our representative to help you complete the selection process.

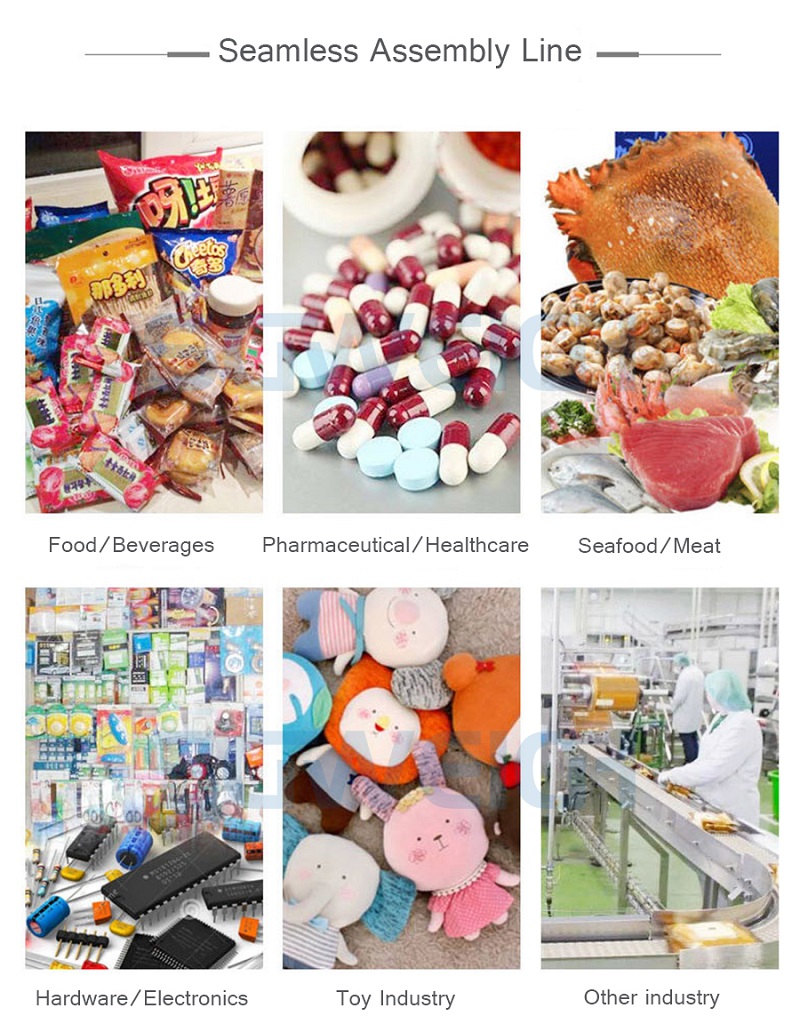

Industrial checkweighers with dual reject system are widely used in the production and packaging processes of industries such as food and beverage, pharmaceuticals, daily chemicals, warehousing and logistics, electronics and light industry, packaging and printing, auto parts and hardware, plastic toys, chemicals, and agricultural and sideline products.

1. Easy-to-use backlit screen with menu-based navigation.

2. Password-protected main menu.

3. Stores up to 100 different product settings for easy setup and quick switching.

4. Equipped with automatic product rejection function.

5. Non-conforming products can be further categorized as below-average or above-average weight.

6. Robust stainless steel chassis for durability and corrosion resistance.

7. Prevents product leakage and consumer complaints related to lost items or underweight packaging.

8. Electric conveyor belt: Passes all products through a weighing scale to ensure no product goes unchecked.

Industrial Checkweigher with Dual Reject System Dynamic Checkweigher Conveyor

The equipment will be securely fixed and then packed into wooden cases for protection during transportation.

Fast delivery guaranteed! The earliest delivery time is 15 days after payment.

1. Seven-day replacement guarantee, one-year warranty, and lifetime maintenance. All products undergo rigorous inspection before sale; you will receive a product without any quality issues.

2. All products provided to customers are original factory manufactured and come with original factory data and accessories.

3. During the warranty period, our company is responsible for repairing parts damaged due to quality issues. For parts damaged outside the warranty period, we will only charge the cost price for replacements. If the equipment is damaged due to human factors, our company will charge the cost price for repairs or replacement parts.

Related Products

Automatic Capsule Checkweigher for Quality Control

Dynamic Multi-Lane 4-Track Checkweigher

Industrial Box Checkweigher for High-Speed Lines

Wide Range Metal Detector for Bag Packing Line

Nuts Grains Multi-Lane Granule Packing Machine

Online Big Bag Conveyor Metal Detector

High-Speed Bottle Rotary Checkweigher

Twin-Lane Checkweigher with Smart Reject

High-Precision Metal Detector Combined With Checkweigher

Pharmaceutical Tablet Blister Pack Checkweigher

Hot Labels: industrial,checkweigher with dual reject system,dynamic,checkweigher,conveyor,quote,price,manufacturer,supplier,factory