High-Speed Bagged Biscuit Checkweigher Automatic Snack Checkweighing System

This automatic bagged snack checkweigher is designed for modern snack production facilities and can be easily integrated into existing packaging lines. The automatic weighing system of high-speed bagged biscuit checkweigher features a user-friendly touchscreen interface, allowing operators to monitor production in real time, adjust weight parameters, and easily generate batch reports. An automatic rejection mechanism quickly removes underweight or overweight bags without interrupting the production process. You are welcome to contact us at any time for quotation.

Automatic bagged snack checkweigher photos

High-Speed Bagged Biscuit Checkweigher Automatic Snack Checkweighing System

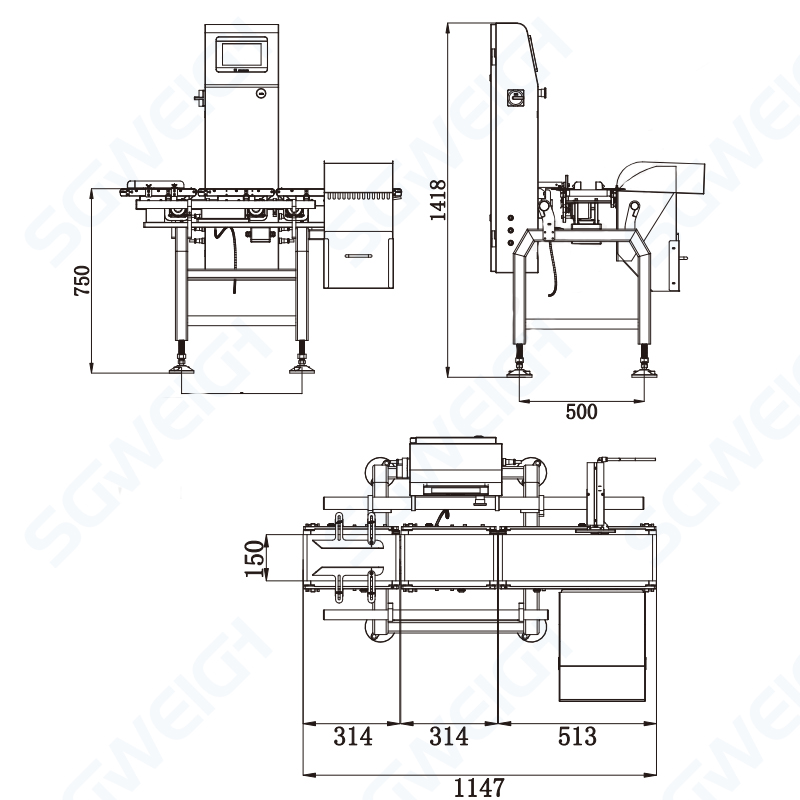

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

1. Precisely measures the weight of each package, detecting weight variations down to the milligram level, ensuring each batch of products meets weight standards.

2. High-speed inspection for maximum production efficiency, reducing human error through automated precision weighing.

3. Real-time monitoring and automatic rejection of defective packages.

4. Hygienic stainless steel design, suitable for cleanroom environments.

5. Easy to calibrate and set up, suitable for various product types, supporting multiple bag sizes and product formulations.

6. Intuitive touchscreen interface with data logging and reporting functions, automatic data acquisition and export, ensuring traceability, and providing detailed statistical reports for compliance audits.

7. Simplifies quality control and regulatory compliance processes.

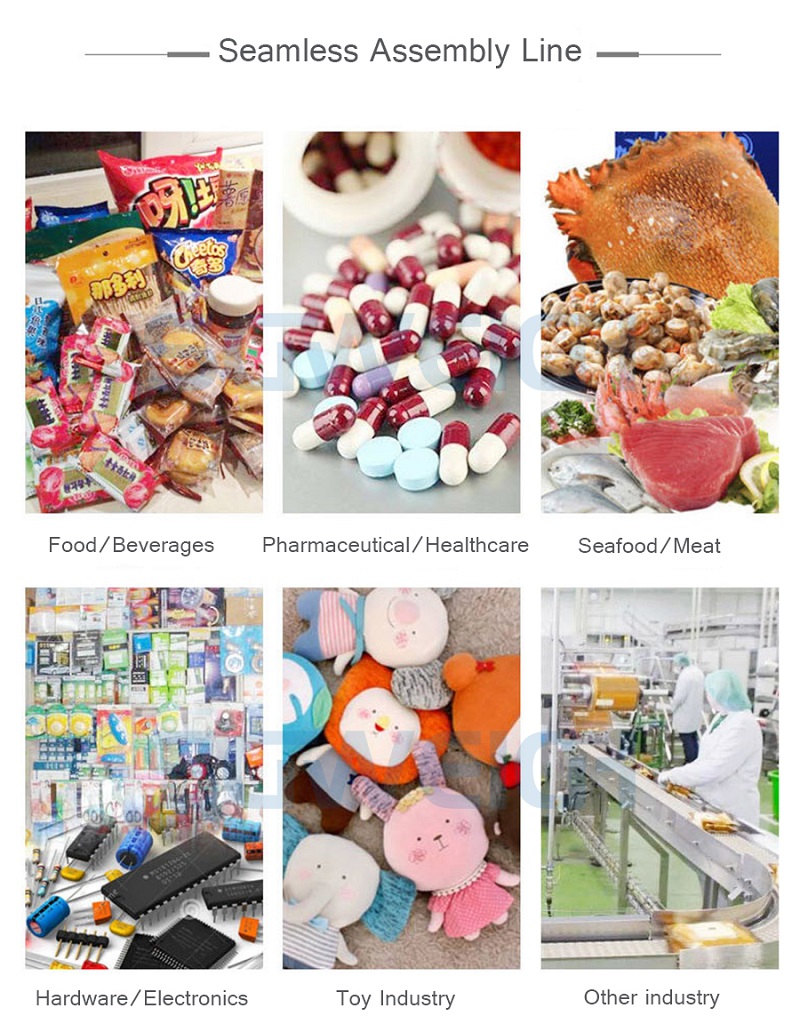

8. Seamlessly integrates with packaging lines for real-time inspection.

9. Modular design, easy to clean, extremely low maintenance, small footprint, suitable for space-constrained production environments.

This automatic bagged snack checkweigher guarantees consistent weight accuracy for chips, nuts, popcorn, and other bagged snacks, reducing giveaway and product loss.

We accept various customizations and logos for all our automatic bagged snack checkweighers for our clients.

If you are interested, please contact us.

If you want to know more about related products, more surprises await you!

High-Speed Bagged Biscuit Checkweigher Automatic Snack Checkweighing System

1. Inner packaging is plastic film, outer is a wooden or plywood box

2. Bare plastic film packaging with only a plastic pallet.

3. We can provide fumigation packaging and certificates.

4. Shipping, training, express, or according to customer requirements.

1. Replacement within seven days, warranty within one year, and lifetime maintenance. Before the products are sold, we will go through strict inspection, and the products you sign for have no quality problems;

2. The products provided to customers are all produced by the original factory, and have factory data accessories;

3. During the warranty period, our company will repair the damaged parts due to quality reasons, and the damage of the parts outside the warranty period. The provided accessories only charge the cost. If the equipment is damaged due to human factors, the parts repaired or provided by our company are calculated at the cost.

Related Products

Pipeline Metal Detector for Sauce Paste Liquid

60kg Rice Checkweigher for Food Packaging Lines

High-Sensitivity Metal Detector for Frozen Diced Vegetables

Smart Multi-Lane Checkweigher for Coffee Sachet

Stick Jelly Multi-Lane Packing Machine

Industrial Checkweigher with Dual Reject System

Food Pharma Multi-Stage Weight Sorting Machine

Automatic Capsule Metal Detection System

Automatic Capsule Checkweigher for Quality Control

Dynamic Multi-Lane 4-Track Checkweigher

Hot Labels: high-speed,bagged biscuit,checkweigher,automatic,snack,checkweighing,system,quote,price,factory,manufacturer,supplier