Food Checkweigher With Metal Detector Combo Tea Bag Weighing Metal Detector

The food checkweigher with metal detector combo integrates metal detectors and weighing scales, automatically detecting different situations such as qualified products, unqualified products, missing products, and containing metal impurities. It will automatically remove unqualified products to ensure the quality of the products leaving the factory. The tea bag checkweigher with metal detector combo can greatly save floor space and has the characteristics of high weighing accuracy, fast detection speed, and strong adaptability. To know more about us, please you do not hesitate to contact us or visit our factory.

Food checkweigher with metal detector combo photos

Food Checkweigher With Metal Detector Combo Tea Bag Weighing Metal Detector

Model SG-JS150

Specifications 4010

Detection of hole width detection 150mm

Inspection hole height 100-200mm

Detection sensitivity

In empty state:(H)100mm ;Fe≥Φ0.8mm,SUS≥Φ1.2mm

(H)120mm ;Fe≥Φ1.0mm,SUS≥Φ1.8mm

(H)150mm ;Fe≥Φ1.2mm,SUS≥Φ2.0mm

(H)200mm ;Fe≥Φ1.5mm,SUS≥Φ2.5mm

Effective hole width detection 150mm

Effective hole detection level 100-200m

Weighing accuracy ±0.1g(Depend on product)

Conveyor height 750mm(±50mm)

Transmission capacity 10kg/times

Transfer direction From left to right

Conveyor belt max speed 25m/min

Material for conveyor belt Food grade PU belt

Protection grade IP65

Display and operation mode LCD flat key input

Deadweight of machine About 240kg

Power supply requirements AC 220V 50HZ

Power About 300w

Overall dimensions About L2267*W589*H1500mm(Design drawing prevail)

1. High speed operation: The combination system is designed for high-speed operation, which will not affect the detection sensitivity or weighing accuracy, and is suitable for fast-moving production lines.

2. Space saving design: By combining the weighing scale and metal detector into one machine, this system saves valuable floor space in production facilities.

3. Centralized control system: A single user-friendly interface allows operators to monitor and control weighing scales and metal detectors, simplifying operations and reducing training requirements.

4. Modular design: The system can customize various conveyor belts, removal mechanisms, and detection sensitivity options to meet specific production requirements.

5. High sensitivity: The metal detector has high sensitivity and can detect the smallest metal particles in the product, ensuring a high level of product safety. The weighing scale provides accurate weight measurement to ensure that the product meets strict quality standards.

6. Improving efficiency: Integrating weight and metal detection functions into one unit reduces the number of detection stages, saves time, and improves production capacity.

7. Cost effectiveness: By integrating two systems into one system, the company can save equipment costs, maintenance, and footprint.

8. Enhance product safety: The dual detection system not only ensures correct weighing of the product, but also does not contain potential hazardous metal contaminants.

9. Reduce downtime: The integrated system simplifies the detection process and reduces the possibility of errors or delays caused by individual machines.

10. Compliant with industry standards: This system helps manufacturers meet regulatory requirements and industry standards such as HACCP, FDA, or GMP by ensuring consistent quality and safety.

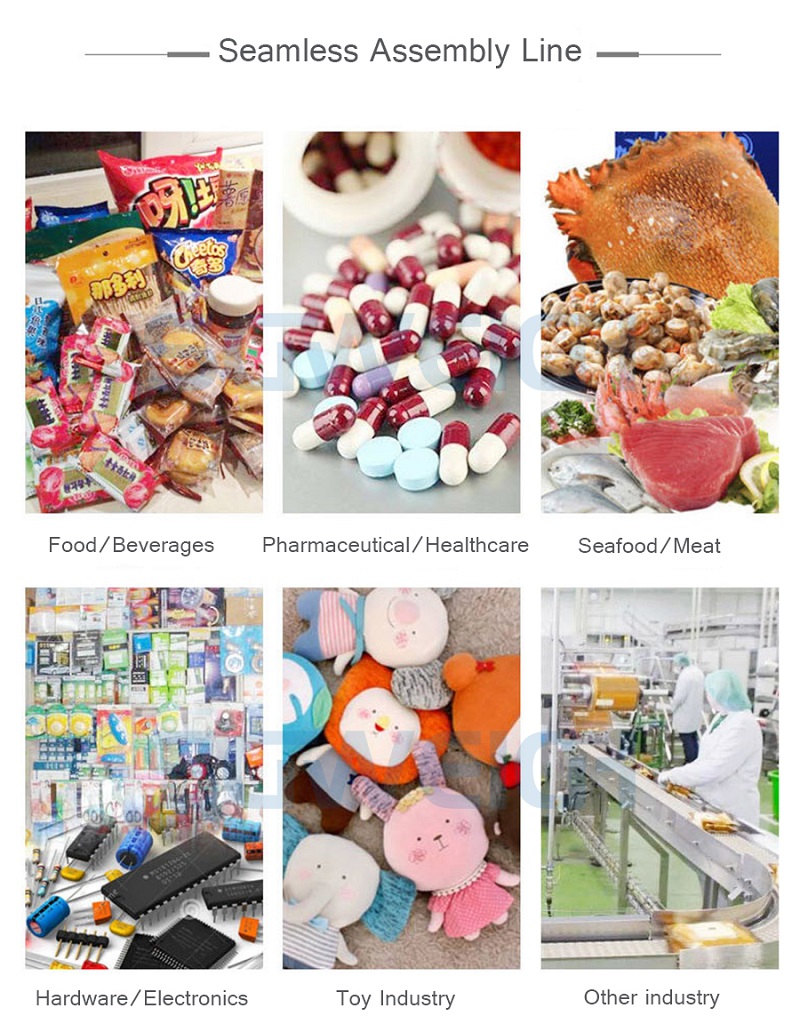

Food checkweigher with metal detector combo is used for post packaging weight and metal detection in fields such as food, pharmaceuticals, chemicals, textiles, toys, etc.

The displayed food checkweigher with metal detector combo may not meet your requirements. Please provide the following information and we will recommend a suitable model for you

1. Determine the series based on the size, weight range, and purpose of the product you need to weigh.

2. Determine the appropriate exclusion system based on your product

3. Determine the height, width (if any), and required space for our company’s existing production line.

4. Determine the features you need to select and equip; Such as USB storage of data, real-time transmission of weight data, alarms, and so on.

In order to provide more accurate parameters, solutions, and quotations, we suggest that you contact our responsible person to assist you in completing the selection.

Food Checkweigher With Metal Detector Combo Tea Bag Weighing Metal Detector

Equipment packaged in export standard wooden crates (fumigation free). We can accept FOB, CFR, CIF terms, and our professional logistics team can handle sea, air, and railway transportation.

1. We will deliver the machines and provide a load list on time to ensure that you can quickly obtain the machines

2. We often ask for feedback and provide assistance to customers who have used our machines in their factories for a period of time.

3 .We offer a one-year warranty

4. Trained and experienced employees will answer all your inquiries in English and Chinese

5.12 months warranty and lifetime technical support.

6. Your business relationship with us will be kept confidential from any third party.

7. Provide excellent after-sales service. If you have any questions, please contact us.

Related Products

Food Metal Detection System For Bag Flour

Pharmaceuticals Capsule Metal Detector System

Intelligent Multi-Lane Checkweigher For Ketchup Bars

Plastic Bottles Checkweigher For Production Line

Ultra-High Speed Pharmaceutical Box Checkweigher

Mini Checkweigher for Capsules & Tablets

High Speed Bag Salt Checkweigher Reject System

Metal Detection Machine With Auto Belt Stop

Heavy-Duty Carton Box Checkweigher

High-Speed Capsule Checkweigher With 1mg Accuracy

Hot Labels: food,checkweigher with metal detector combo,tea,bag,weighing metal detector,price,manufacturer,factory,supplier