Cup noodle Check Weigher Metal Detector Combo Food Auto Weighing Metal Detector

The cup noodle check weigher metal detector combo integrates weighing and metal detection functions, occupies a small area, has a compact structure, and is easy to install and maintain. The food auto metal detector with checkweigher has the characteristics of high weighing accuracy, fast detection speed, and strong adaptability. It can effectively improve the production efficiency and product quality of enterprises and meet the needs of modern industrial production. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

Cup noodle check weigher metal detector combo photos

Detection method: electromagnetic induction / digital weighing sensor

Size: 330×150mm

Accuracy: FE0.8mm SUS2.0mm

Sorting accuracy: ±0.5g

Weighing range: 5g-900g

Passing height: 110mm

Passing width: 280mm

Packaging length: ≤300mm

Display division value: 0.1g 0.2g 0.5g 1g

Number of sorting sections: 3 sections

Sorting capacity: 60 times/minute

Conveyor belt speed: 10-45m/minute

Ground height: 735mm-800mm

Working temperature: 0-40℃

Weight: about 160kg

Dimensions: 1900mm×700mm×1120mm (L×W×H)

Cup noodle Check Weigher Metal Detector Combo Food Auto Weighing Metal Detector

Cup noodle check weigher metal detector combo is mainly used for accurate weighing and metal detection of raw materials, semi-finished products and finished products in food, pharmaceutical, chemical and other industries.

1. High-Speed Operation: The check weigher metal detector combo system is designed to operate at high speeds without compromising detection sensitivity or weighing accuracy, making it suitable for fast-moving production lines.

2. Space-Saving Design: By combining the checkweigher and metal detector into one machine, the system saves valuable floor space in production facilities.

3. Centralized Control System: A single user-friendly interface allows operators to monitor and control both the checkweigher and metal detector, simplifying operation and reducing training requirements.

4. Modular Design: The system can be customized with a variety of conveyor belts, reject mechanisms, and detection sensitivity options to meet specific production requirements.

5. High Sensitivity: The digital metal detector has high sensitivity and can detect the smallest metal particles in the product, ensuring a high level of product safety. The checkweigher provides accurate weight measurement, ensuring that the product meets strict quality standards.

6. Improved Efficiency: Combining the checkweighing and metal detection functions into one unit reduces the number of detection stages, saving time and increasing production capacity.

7. Cost-Effectiveness: By combining the two systems into one, companies can save on equipment costs, maintenance, and floor space.

8. Enhanced Product Safety: The dual detection system not only ensures that the product is weighed correctly, but also does not contain potentially dangerous metal contaminants.

9. Reduced downtime: Food check weigher metal detector combo systems streamline the inspection process, reducing the potential for errors or delays caused by individual machines.

1. Sensitivity Adjustment: The metal detector can be calibrated to detect different sizes and types of metal particles, ensuring it is suitable for the specific product being inspected.

2. Product Size Adjustment: The system can be customized to accommodate different product sizes and packaging formats, ensuring flexibility across a variety of production lines.

3. Customized Rejection Mechanism: Depending on the size, weight and fragility of the product, different reject systems such as airflow, pushers or drop stops can be used to reject non-compliant products without damaging the product.

4. Conveyor Speed and Width: Conveyor speed and width can be adjust to the specific needs of the production line, ensuring that the combined system fits seamlessly into the existing workflow.

Cup noodle Check Weigher Metal Detector Combo Food Auto Weighing Metal Detector

Machine packing :

Non-fumigation wooden case for export standard and comply with customs clearance requirement

Lead time :

10-15 days after payment received

Price term :

FOB term, CIF/CFR term(sea/air), DDU/DDP term( sea/air)

Negotiable payment term: T/T , LC, D/P ,D/A .,etc

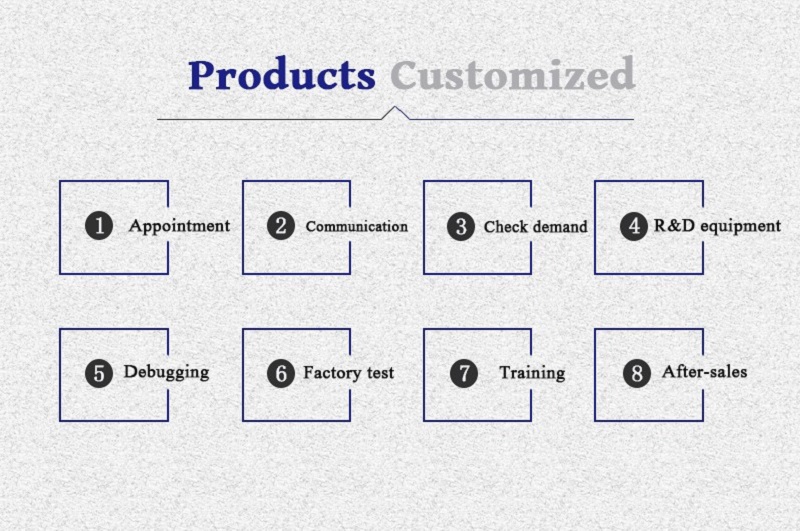

1. Consultation and Evaluation: Understand the customer’s requirements, production processes and quality control goals, and determine the machine solution that best suits their specific needs.

2. Product Demonstration: Visually see the operation of the equipment and directly evaluate its performance.

3. Installation and Commissioning: After purchase, the machine is install and commissioned by trained technicians to ensure it operates correctly and integrates seamlessly into the customer’s production line.

4. Technical Support: Provide ongoing technical support to resolve any questions, problems or maintenance needs that arise during the operation of the machine.

5. Warranty Coverage: 1 year warranty, lifetime repair.

We aim to provide customers with the right solutions, support and peace of mind throughout the life cycle of the equipment, ensuring that the machine meets the customer’s needs and provides long-term value.

Related Products

10 Lanes Stickpack Multi-Lane Checkweigher

Gel Capsule And Tablet Metal Detector With Rejection

Rotary Turntable Checkweigher For Bottle Production Line

Milk Bottle High Speed Weight Checking Machine

Hairy Crabs Multi-Level Weight Sorting Checkweigher

Online Nut Sachet Checkweigher With Rejection

Probiotics Powder Multi-Row Packing Machine

Professional Capsule And Tablet Checkweigher

Meat Paste Pipeline Conveyor Metal Detector

Touch-Sensitive Boxed Spices Checkweigher

Hot Labels: cup noodle,check weigher metal detector combo,food,auto,weighing metal detector,manufacturer,supplier,price,factory