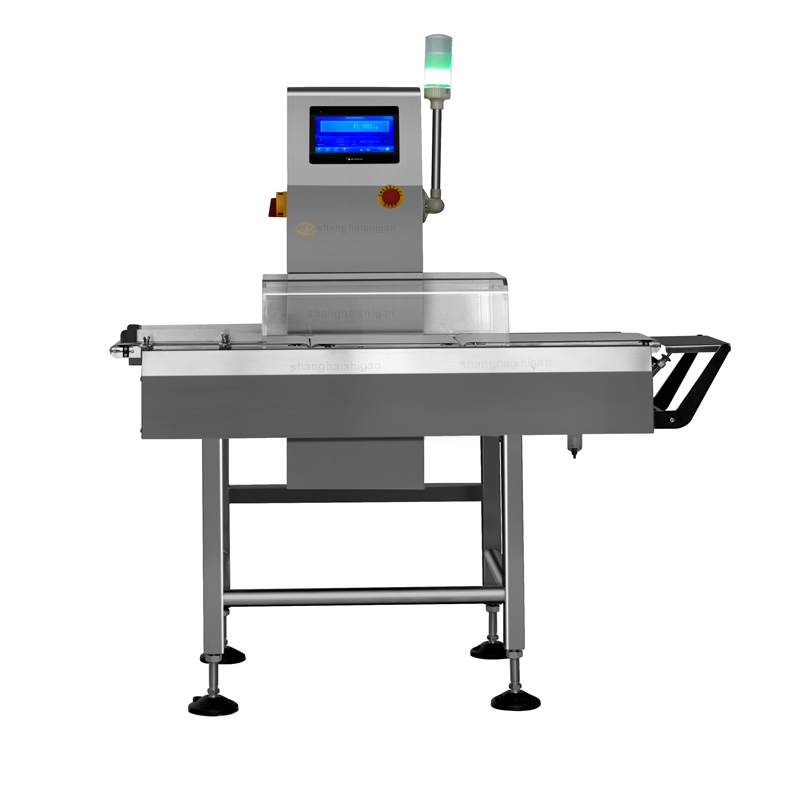

Bottled Calcium Tablet Checkweigher Pharma Package Weight Inspection System

This high accuracy bottled calcium tablet checkweigher verifies the weight of bottled products online, and the high-precision weighing sensor and fast-response conveyor system can easily handle bottles of various shapes and sizes, ensuring that each product meets weight specifications before reaching the customer. The pharma package weight inspection system can be easily integrated into existing tablet filling and capping lines, maintaining smooth and efficient operations without reducing production efficiency. You are welcome to contact us at any time for quotation.

High accuracy bottled calcium tablet checkweigher pictures

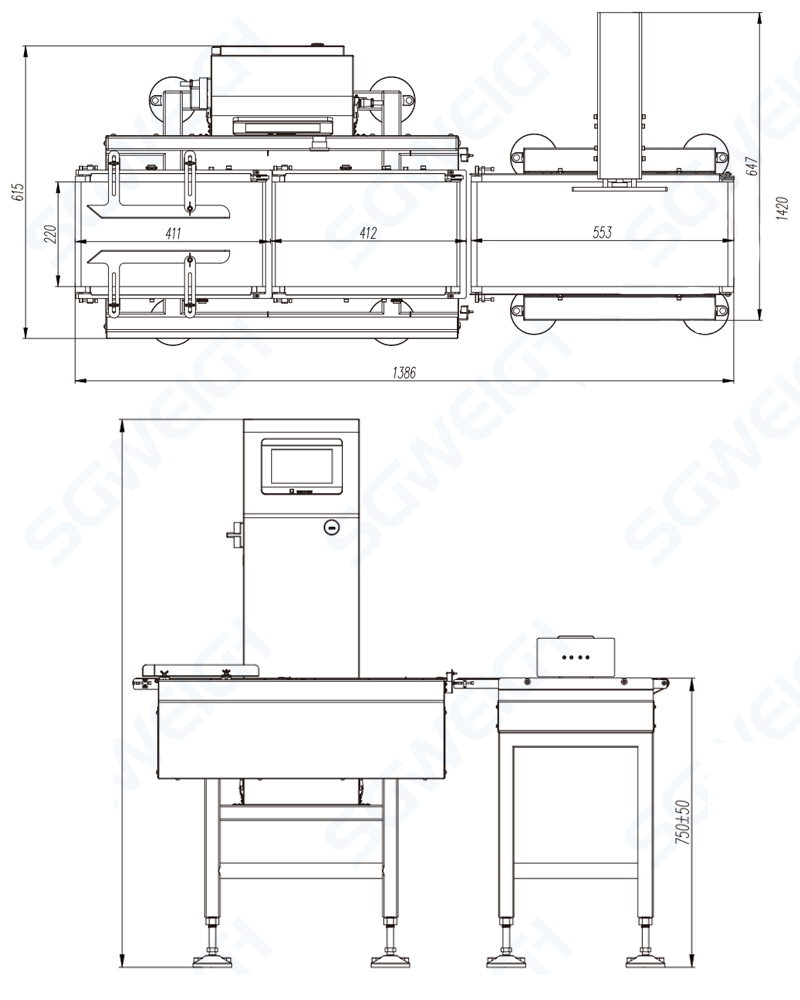

Type SG-220

Weighing Range 5-1500g

Limited of product L: 300 W:220 H: 3-200mm

Accuracy ±0.2g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 100 pcs/min

Belt Width p220mm

Machine Weight 85kg

Power Supply AC-220V 50HZ

Power 200W

Main Material SU304 stainless steel

Bottled Calcium Tablet Checkweigher Pharma Package Weight Inspection System

1.High performance and maximum efficiency.

2.Large load range with extreme precision.

3.Designed for demanding production environments.

4.Flexible and efficient product handling.

5.Low maintenance costs.

6.Improve production line efficiency. Equipment efficiency across the entire line is improving.

7.The accuracy of the weighing machine ensures that customer interests are not affected.

8.Reduce potential sampling errors and long-term labor costs.

9.Improve product quality to meet customers’ strict needs.

10.Cost savings increase product profits.

High accuracy bottled calcium tablet checkweighers are widely used in the production and packaging processes of food and beverage, pharmaceutical, daily chemical, warehousing and logistics, electronic light industry, packaging and printing, auto parts and hardware, plastic toys, chemical, agricultural and sideline products and other industries.

When selecting an automatic bottle checkweigher, consider the following factors:

1. Production speed and throughput

2. Bottle size, shape, and material

3. Weight accuracy requirements

4. Integration with existing production lines

5. Data collection and reporting capabilities

6. Budget

Bottled Calcium Tablet Checkweigher Pharma Package Weight Inspection System

1> Attach safety labels, tighten screws, clean, lubricate, and prevent rust;

2> Disassemble into packages;

3> Wrap tightly with plastic film;

4> Fix in plywood box

5> Forklift enters container

Suitable for long-distance land and sea transportation. In order to safely load and unload to the destination, we recommend that you choose full container transportation.

1. Customer consultation and technical support: Provide customers with consulting services on product use, repair and maintenance, and answer questions encountered by customers during operation and use.

2. Technical training: Provide training on product operation, maintenance and repair according to customer needs to ensure that customers can use and maintain the products correctly.

3. Accessories supply: Provide original accessories to ensure the quality and performance of accessories to meet user needs.

4. One-year warranty, lifetime maintenance

5. After-sales service tracking: Track and feedback the after-sales service process, timely understand customer needs and opinions, and continuously improve service quality.

Related Products

Digital Metal Detector For Meat Processing

Automatic Checkweigher System For Baked Food Production

Pharmaceutical Compact Capsule Metal Detector

Online High Speed Check Weigher With Rejection

Sachet Multilane Sauce Filling Packing Machine

Foil-Wrapped Medicine Product Metal Detector

High Accuracy Hard Capsule Checkweigher

Powder Free-Fall Metal Detector With Rejector

Candy Snacks Production Line Checkweigher

Online Checkweigher For Vacuum Sealed Foods

Hot Labels: bottled,calcium tablet,checkweigher,pharma,package,weight inspection system,manufacturer,supplier,price,factory