Automatic Inline Checkweigher for Tube Pharmaceutical Cosmetics Weight Checker

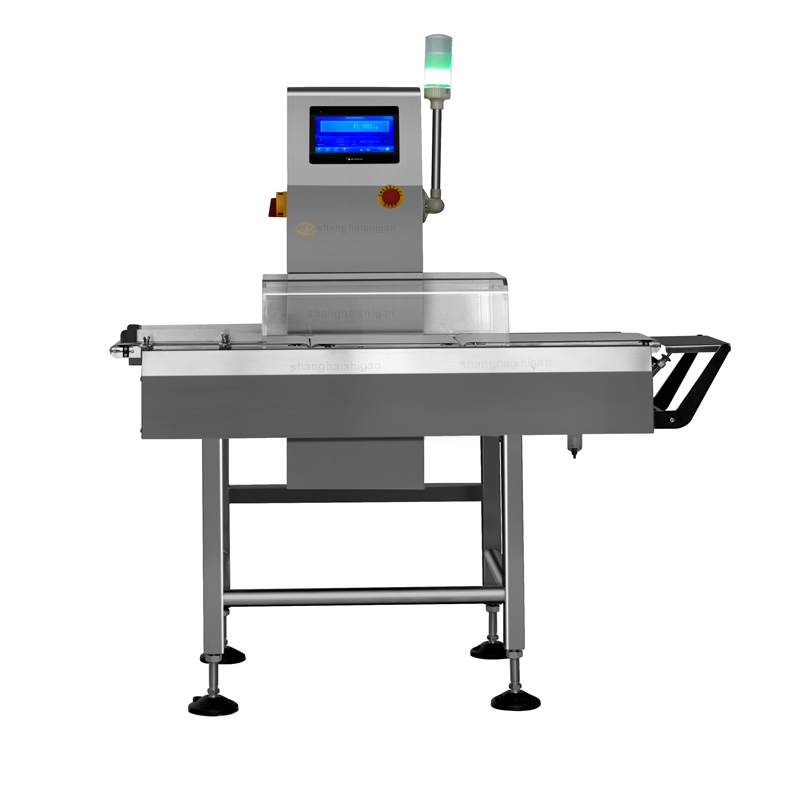

The tube pharmaceutical cosmetics weight checker uses advanced load cell technology and anti-vibration design to maintain accurate weighing even on high-speed production lines, regardless of packaging changes. This automatic inline checkweigher for tube is equipped with an intuitive touch screen interface, customizable weighing parameters, and can automatically reject non-compliant materials. The modular structure allows for quick installation. You are welcome to contact us at any time for quotation.

Tube pharmaceutical cosmetics weight checker photos

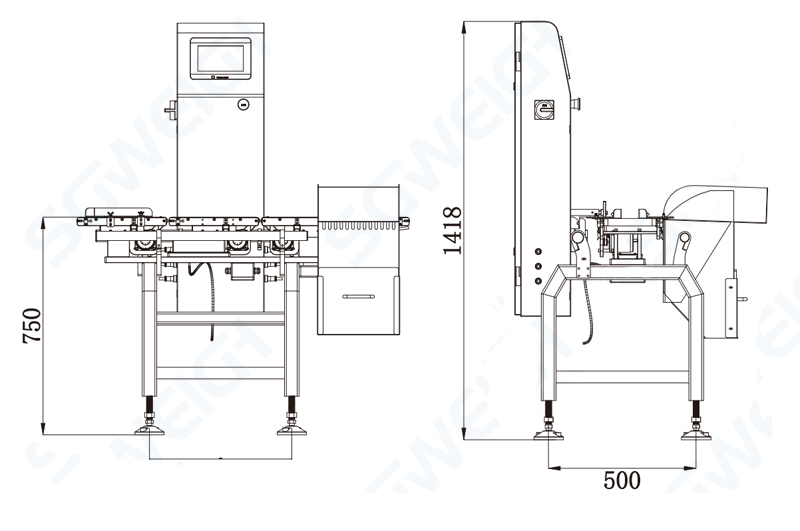

Type SG-150

Weighing Range 3-500g

Limited of product L: 200 W:150 H: 3-200mm

Accuracy ±0.1g Depends on product

Division Scale 0.1g

Belt Speed 0- 60 m/min

Max Speed 150 pcs/min

Belt Width 150mm

Machine Weight 80kg

Power Supply AC 110/220V ±10% 50HZ

Power 100W

Main Material SU304 stainless steel

Automatic Inline Checkweigher for Tube Pharmaceutical Cosmetics Weight Checker

1. This tube pharmaceutical cosmetics weight checker uses high-speed, low-noise bass motors and bearings as transmission components to reduce the hazards of noise and interference.

2. To prevent electromagnetic and radiation hazards, this machine uses excellent shielding materials to shield various electromagnetic hazards and interference.

3. Provide a high-definition touch screen as a simple user interface.

4. The conveying system consists of a brushless motor and a conveyor belt. The brushless motor drive module provides the motor with high torque, high precision, and a wide speed range drive, which realizes the uniform movement of the items and enables the weighing unit to detect the weight of the items more accurately.

5. The tube pharmaceutical cosmetics weight checker consists of a main weighing unit and a vibrating weighing unit. The high-speed checkweigher adds a vibrating weighing unit to prevent external vibration. The weighing vibration unit uses a high-precision, high-speed, and high-sensitivity weighing sensor. The information that the item is forced to rotate is converted into an electrical signal by the weighing module through the sensor, and is displayed on the touch screen after communicating with the single-chip microcomputer.

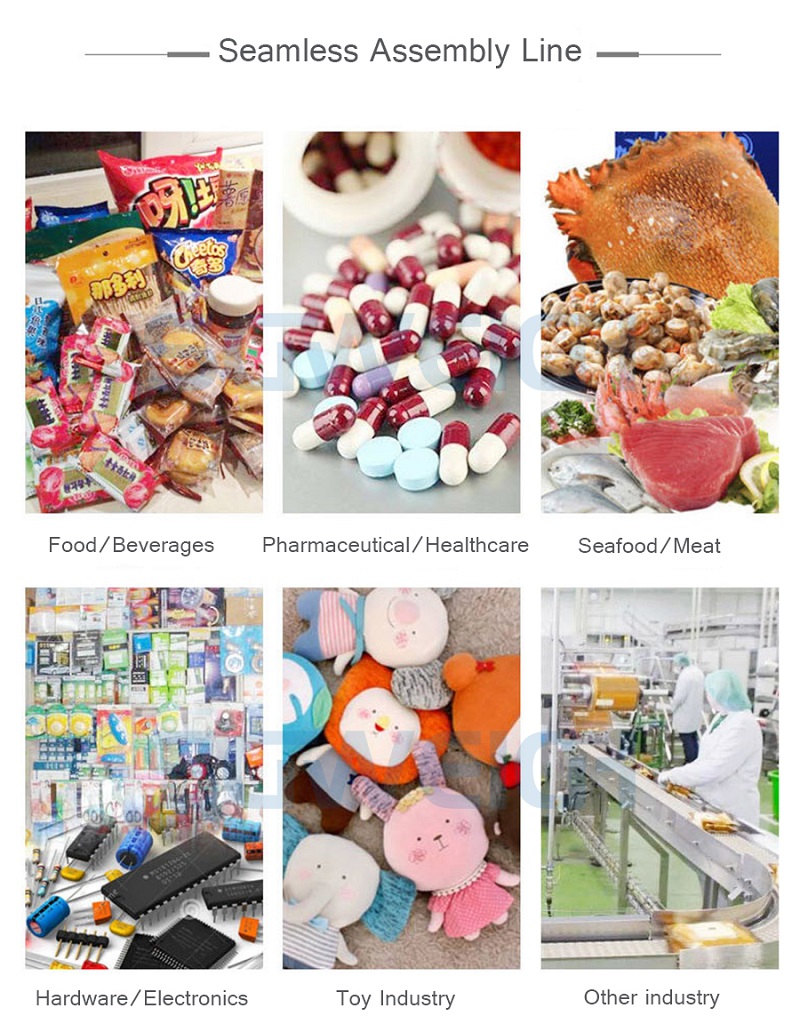

Automatic inline checkweigher for tube is an automatic weight inspection equipment for production lines widely used in pharmaceutical, food, chemical and other industries. It can detect overweight and underweight unqualified products in the production line in real time online and automatically remove unqualified products.

1st step: Customer has showed his special requirements.

2nd step: We try to understand the conception and pattern from customer with simple draft or refer picture.

3rd step: Making the conceptive CAD drawing based on communication and understanding.

4th step: Making the detail and 3D drawing agter fixed the design and other details.

5th step: Offer the quotation after confirm the design,material and surface treament.

6th step: Making the sample for approval.

7th step: Testing installation after demo mock up.

8th step: Big production delivery and service after sales.

Automatic Inline Checkweigher for Tube Pharmaceutical Cosmetics Weight Checker

The whole automatic inline checkweigher for tube is packed in two layers

Pre-packaging uses plastic bags to transport the whole machine, and key components are protected by foam plastics

Engineering packaging uses sturdy polyethylene wooden boxes that meet the import standards of different countries

Installation and use

After unpacking, lift the rubber base and move it to your working position with wheels.

1. Service tenet: Shanghai Shigan Industrial Co., Ltd. is committed to providing customers with fast, decisive, accurate, thoughtful and thorough services to meet customers’ needs in equipment.

2. Service goals: The company takes high-quality service quality as the standard, aiming to win the satisfaction and trust of users.

3. Service efficiency: The company promises that once the equipment fails, it will provide an effective solution within 24 hours to ensure that the customer’s production progress is not affect.

4. Service principles: The company’s product warranty period is twelve months. During the warranty period, the supplier will provide free repairs and replacement parts for equipment damage caused by quality reasons. For equipment parts damaged outside the warranty period, the supplier will only charge the cost price. For equipment damage caused by customer human factors, the supplier’s repair or parts provision will be calculate at cost.

Related Products

High-Speed Rotary Weighing Checkweigher for Bottles

Combination Metal Detector and Checkweigher System

Automatic Pharmaceutical Checkweigher for Box

High-Sensitivity Metal Detection Machine for Tablets

Strip Sachet Multi-Lane Packing Machine for Pastes

Pouch Automatic Industrial Checkweigher Price

Box High Accuracy Checkweigher Inspection System

High-Precision Multi-Lane Checkweigher for Stick Package

Real-Time High-Precision Capsule Checkweigher

Carton Packaging Line Industrial Weight Checker

Hot Labels: automatic,inline,checkweigher,tube,pharmaceutical,cosmetics,weight checker,price,manufacturer,supplier,factory