Multi-Conveyor Line Checkweigher for Honey Stick Packs 10-Lane Checkweigher

The automated multi-conveyor line checkweigher for honey stick packs is engineered to inspect multiple stick packs simultaneously, reducing errors and maintaining consistent weight verification across all lanes, minimizing waste and production downtime. The stick packs 10-lane checkweigher system’s intelligent sensors instantly detect underweight and overweight products and automatically reject non-compliant packs, ensuring every unit meets your precise specifications. Our products have a wide range of specifications, sizes, and styles, providing various customized solutions. Welcome to contact us.

Multi-conveyor line checkweigher for honey stick packs photos

Multi-Conveyor Line Checkweigher for Honey Stick Packs 10-Lane Checkweigher

The multi-conveyor line checkweigher for honey stick pack is suitable for detecting product shortages in industries such as food, pharmaceuticals, daily chemicals, electronics, machinery, and printing.

It automatically checks whether the weight of packaged finished products is within acceptable limits, and sorting eliminates unqualified items.

Type SG-10XM

Weighing Range 2-300g

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Each Channel Speed 70 pcs/min

Belt Width 30mm

Machine Weight 200kg

Power Supply AC 110/220V ±10% 50HZ

Power 300W

Main Material SU304 stainless steel

We accept various customizations and logos on all our products.

If you’re interested, please contact us.

If you’d like to learn more about related products, there are more surprises waiting for you~

1. Enables online weighing of products during dynamic operation.

2. Enables dynamic weighing according to preset weight requirements.

3. 100% automatic weight detection of each product.

4. Standardized weight detection and quality control weight parameter testing based on line speed.

5. Automatically rejects unqualified products or performs quality grading.

Multi-Conveyor Line Checkweigher for Honey Stick Packs 10-Lane Checkweigher

1> Attach safety labels, tighten screws, clean, lubricate, and rust-proof.

2> Unpack into packaging.

3> Wrap tightly with plastic film.

4> Secure in plywood crates.

5> Load container by forklift.

Suitable for long-distance land and sea transportation. For safe loading and unloading at the destination, we recommend FCL shipping.

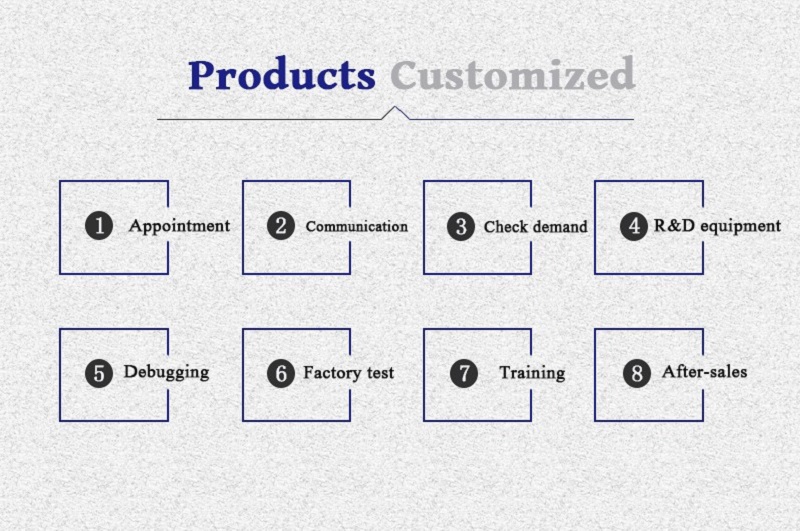

Consultation and Evaluation: We understand our customers’ requirements, production processes, and quality control goals, and determine the machine solution that best suits their specific needs.

Product Demonstration: We provide a visual demonstration of the equipment in action and a direct assessment of its performance.

Installation and Commissioning: After purchase, the machine is installed and commissioned by trained technicians to ensure correct operation and seamless integration into the customer’s production line.

Technical Support: We provide ongoing technical support to address any questions, issues, or maintenance needs that arise during machine operation.

Warranty Coverage: One-year warranty and lifetime repairs.

We aim to provide customers with the right solutions, support, and peace of mind throughout the equipment’s lifecycle, ensuring the machine meets their needs and provides long-term value.

Related Products

Super-Sensitivity Metal Detector for Foil-Packed Medicines

Automatic Box Product Checkweigher for Production Lines

Overweight Underweight Inspection Checkweigher

High-Accuracy Checkweigher with Metal Detector Combo

Multi-Lane Packaging Machine for Solid Beverages

Production Lines Metal Detector for Beverages

Automatic Dynamic Checkweighing for Boxes Conveyor

Combination Metal Detector and Checkweigher System

Bottle Checkweigher with Rotary Turntable Design

Pharmaceutical Metal Detector for Capsules and Tablets

Hot Labels: multi-conveyor line,checkweigher,honey,stick packs,10-lane checkweigher,suppliers,quote,price,manufacturer,factory