High Precision Industrial Rotary Checkweigher for Bottles with Rejection System

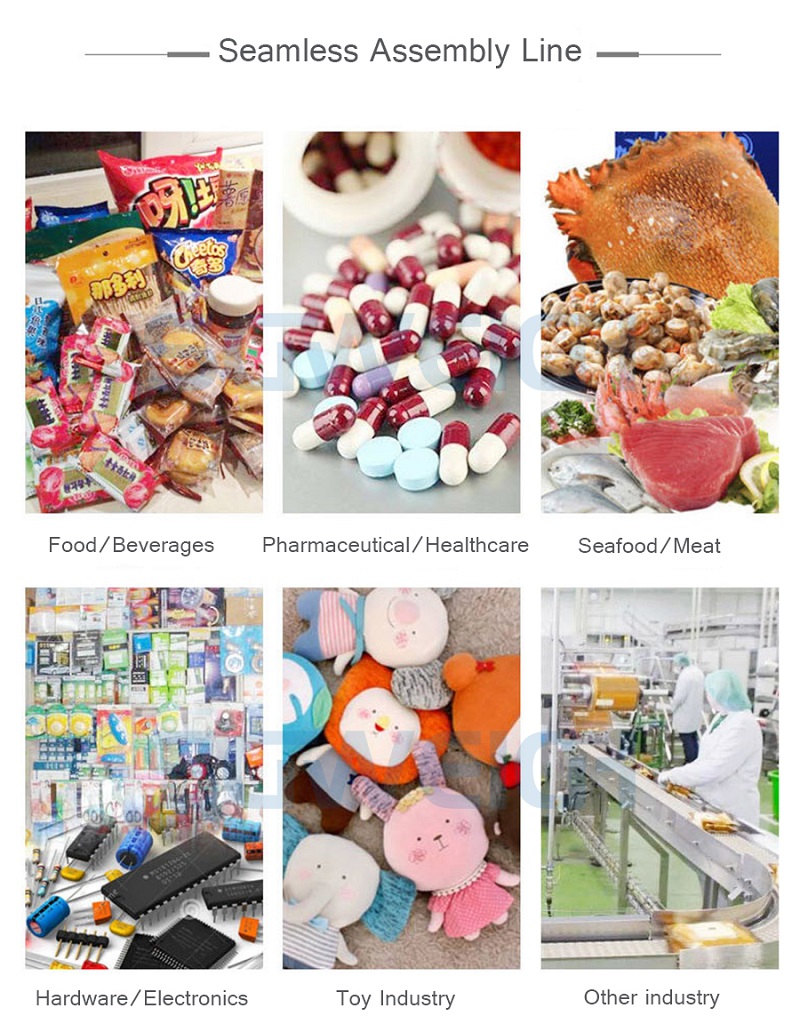

The high precision rotary checkweigher for bottles is an automatic device used in automatic packaging production lines to check the weight of products. It can check whether the weight of products meets the standard weight we set during continuous operation. The entire industrial rotary checkweigher for bottles is made of 304 stainless steel, and unqualified products are automatically alarmed and removed, solving the work efficiency of automated production lines. Any OEM and customer design orders are welcome! If you are interested in our products, please feel free to contact us.

High precision rotary checkweigher for bottles photos

Type SG-Z

Weighing Range 2-300

Restrictions of Products:φ10-100 H:20-200mm

Limited of product L: 180 W: 40 H: 2-20mm

Accuracy ±0.01g Depends on product

Division Scale 0.01g

Belt Speed 0- 50 m/min

Max Speed 60 pcs/min,120 pcs/min,180 pcs/min(optinal)

Belt Width 100mm

Machine Weight 260kg

Power Supply AC 110/220V ±10% 50HZ

Power 400W

Main Material SU304 stainless steel

The rotary checkweigher for bottles displayed may not meet your requirements. We have professional technical staff to provide professional customized solutions based on the user’s product characteristics and application scenarios.

1. Online weighing of products during dynamic operation can be realized

2. Dynamic weighing detection can be carried out according to the preset weight requirements.

3. Can 100% automatically detect the weight of each product

4. Can be adjusted according to the assembly line speed. Quality inspection weight parameters for standardized weight inspection and troubleshooting

5. Automatically remove products with substandard weight or classify quality

- Large screen display,clear viewing and convenient operation

- Chinese-English interface( Multiple languages can be customize)

- Photoelectric positioning, the turntable accurately sends the product to the load cell

- Chain conveyor is strong and durable

- Three-level operation authority management, support self-set Password

- 100 kinds data can store with strong data statistics function.

- Unqualified products are automatically rejected (push type, air blowing type are optional)

- Multi-channel passing products to improve production eficiency (the number of channels can be customized)

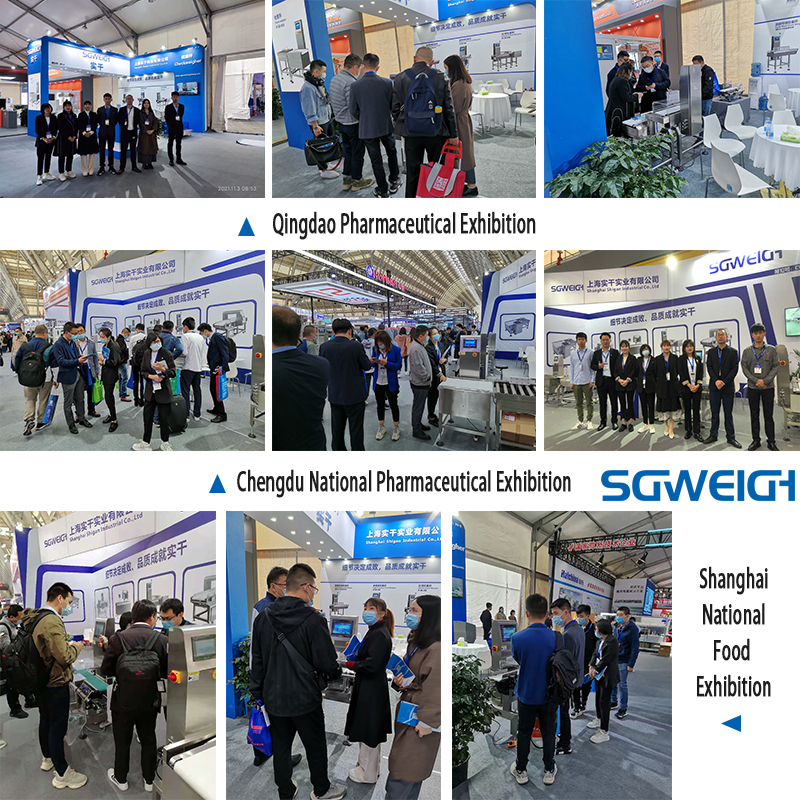

Shanghai Shigan Industrial Co,. Ltd established in 2010. Since its establishment, it has been engage in the research and development and production of fully automatic checkweigher machine, digital metal detector, weighing labeling machine equipment. Its products are export to international markets. It strictly controls all links and conducts scientific production management to provide high-precision and high-quality delivery of products. .

As a leader in the field of dynamic weighing, Shanghai Shigan always adheres to the concept of “integrity, innovation, cooperation and win-win”, adheres to the customer-centered and quality-based approach, and continuously provides customers with high-quality products and thoughtful services. Shanghai Shigan is willing to cooperate with customers all the time.

Main Products

The Delivery Date: After receiving the payment, the delivery date will be within 15-30 working days

Packaging: Protective film + wooden case

Logistics: Air, sea or express (DHL, etc.)

The Freight: The cost of transport depends on the destination, mode of transport and the weight of the goods

Pay: T/T, Western Union, paypal

1. Service purpose: Shanghai ShiGan Industrial Co., Ltd. is commit to providing customers with fast, decisive, accurate, thoughtful and thorough services to meet customers’ equipment needs.

2. Service goals: The company takes high-quality service quality as its standard and aims to win user satisfaction and trust.

3. Service efficiency: The company promises that once equipment fails, it will provide effective solutions within 24 hours to ensure that the customer’s production progress is not affect.

4. Service principle: The company’s product warranty period is twelve months. During the warranty period, if the equipment is damage due to quality reasons, the supplier will provide repair and replacement parts free of charge. If the equipment parts outside the warranty period are damage, the supplier will only charge the cost price. For equipment damage caused by customer factors, the supplier’s repair or parts provision will be calculate at cost.

Related Products

Dynamic Multi-level Weight Sorting Checkweigher

Fluid Product Pipeline Metal Detection Machine

Automatically Reject Capsule Tablet Sample Check Weigher

Inline Industrial Metal Detector and Checkweigher Combo

High Quality Meat Food Metal Detector For Aluminum Foil

SG-220U Boxed High Speed Inline Checkweigher

Hot Labels: high precision,industrial,rotary,checkweigher for bottles,rejection,system,check weigher, price,factory,maunufacturer